In our industry we are often asked: What’s the gloss on the floor? Or, did you hit the gloss readings that are in the specification?

Let’s discuss this from a couple points. First off, where did the concept of “gloss” even come from, or how was this brought into the industry? Second, let’s see how this can hurt you and help you. Third, did you do chemicals, not the illegal ones but the “cheating” ones?

Last but not least. let’s look at the Concrete Polishing Association of America and how we are industry people working on a standard for the industry.

Gloss readings came about because of the “big box” retailers and the architects as a way to validate the finish on a finished concrete floor. In the beginning the thought process was that you wanted an extremely shiny or a high-gloss floor. Early specifications called out for gloss readings in the 50 or 60 range. As you all know, this is the typical shine sought after by extremely high-end retailers.

This look is great for moderate foot traffic. But for use in a warehouse-type setting or home improvement setting with lots of foot and forklift traffic this specification became unrealistic. Remember the higher the shine on a floor, the more maintenance that will need to be done in order to keep this shine. Think of a Lamborghini off the showroom floor.

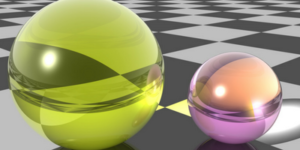

Let’s define what we are actually talking about before we get too deep into this conversation. Most of us in the industry are familiar with Horiba Gloss Meters. When we are talking finished concrete floors we are looking to measure the specular reflection in a surface. This is typically done at the 60-degree setting on your machine. Make sure you calibrate your device. (We will get into the CPAA definition of “gloss readings” in a bit.)

Typically gloss readings are taken in a pattern or a grid-type setting with so many readings per so many square feet per floor. You throw out the high and the low and gain an average reading of the surface. To clarify, this is not where we set the gloss meter on the floor and demand each section read exactly the same way.

Typically gloss readings are a blessing in disguise for applicators and manufacturers who work together on projects. When you have a properly educated owner, architect and general contractor, you can sit and discuss how a gloss meter can be used as a device that will allow all parties to fully execute a specification after setting out guidelines. You can talk about how to actually measure what has been done on a floor.

In some cases we need to examine what could possibly go wrong on a floor and why it would not meet a specification. Carbonization, poor mix design, and so on can all play a part in a floor not meeting the gloss requirements.

Misusing guard

When discussing these poor finishes or these poor conditions, for some of you one word comes into play: GUARD. Now calm down — some of you, not all of you, are victims of this product, but to be quite frank it’s your own fault and, yes, also the fault of some salesperson out there. Guards are a great product and are needed in this industry without a doubt, but in the proper setting and the proper design in a facility. What we typically criticize is the abuse these products received in their early years and still in some situations today, creating what is otherwise known as the “chemical shine.”

There have been many advancements in guard technology, and when used correctly they provide owners and architects with the floor that was envisioned. But they should not be used at 100 or 200 grit to achieve a gloss reading to get out of a job.

My advice is to obtain the gloss reading before the application of any protective treatment that is on the market today.

Establishing gloss standards

What the Concrete Polishing Association of America is trying to do for its industry is define what actual gloss readings are and what we should be focusing on.

I want to describe what we are looking at in the CPAA.

1. Reflective clarity: When viewed five feet above and perpendicular to a surface, the degree of sharpness and crispness of the reflection of overhead objects.

2. Reflective sheen: When viewed at 20 feet from and at an angle to a surface, the degree of gloss reflected from a surface.

When discussing the above, what we want to achieve is the clarity or the crispness of an image in the floor or how well can you read a logo in that reflection.

Whether you are working on a retail store or a garage, understand what you and your customer are looking for when you are discussing the completed surface. A gloss meter is a great tool when used properly and when spelled out in the specifications that you are working on. Take charge on a job whether you are bidding it or whether you are designing it. Know the function of the space and what will it be used for. This will help determine how you specify gloss. And oh yeah, the best floors are the ones in which a 30-to-40 gloss reading is achieved before guard.