Do you know the single-most important ingredient in a concrete countertop that can make or break a business? If you thought concrete, think again. It might surprise you to know that it is actually countertop sealers. You can make the most beautiful concrete countertop in the world, but in the […]

Author: Jeffrey Girard, P.E.

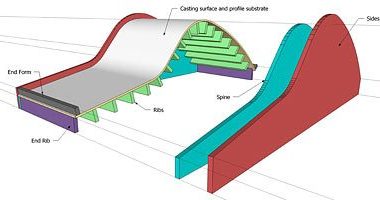

How to Fabricate Molds for Concrete

Forms serve many functions beyond simply containing the concrete. The formwork defines the precision and, to some extent, the quality of the casting. Well-made forms create straight lines, fair curves and right angles and lead to easy, effortless installation.

Design to Delivery in 4 Days – How to make a GFRC Table

Glass-fiber reinforced concrete (GFRC) lets you explore many aspects of design that are not possible with the more traditional precast methods. While GFRC is often used for countertops, we’ll delve into how it can be used to construct a GFRC base for an outdoor patio table.

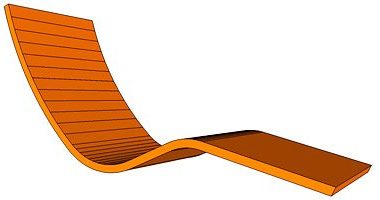

How to Build a Concrete Lounge Chair

Concrete lounge chairs are one of the hottest applications of concrete furniture made with glass fiber reinforced concrete (GFRC).

Which Concrete Countertop Casting Method is Best for the Job?

Concrete is a fantastic material with which to work and design. It is one of the few building materials we can create and control to suit our wants and needs. Mix design, reinforcing technique and casting method are interrelated and influence everything from performance, cost and ease of fabrication to aesthetics and transportability.

A Guide to Building Concrete Fire Features

Throughout the United States and Canada, even in cold climates, homeowners are clamoring for outdoor kitchens and living spaces, using concrete as the material, to enhance the beauty, comfort and resale value of their homes.

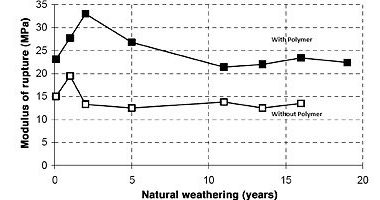

The Importance of Polymer Content in Trustworthy GFRC Mix Designs

Glass-fiber reinforced concrete (GFRC) is a highly specialized form of concrete distinguished by a cement-rich mortar containing a very high load of alkali-resistant glass fibers. The fibers are the main ingredient responsible for producing high flexural (or bending) strengths in GFRC.

How Polymer Additives Became a Part of GFRC

Glass-fiber reinforced concrete became a commercially viable material in the early 1970s. But it would take another decade or two before it became an economically attractive and faster alternative to the heavy and expensive materials traditionally used in commercial buildings.

How to Combat Common Misconceptions about Concrete Countertops

Concrete countertops have been around for decades now, and more and more magazines and TV shows are featuring them. So you wold think misconceptions such as “concrete countertops are cheap” or “concrete countertops are high-maintenance” would be a thing of the past.

Casting Thin Concrete Furniture with GFRC

The acceptance of glass-fiber reinforced concrete (GFRC) has inspired a current trend toward light, thin and delicate concrete furniture.

To illustrate what GFRC can do in furniture form, Jeffrey Girard of The Concrete Countertop Institute describes three projects — a table, a lounge chair and an S chair — that show off the strengths of the material.