To decorative concrete contractors, surface retarders are valuable tools for both pragmatic and aesthetic reasons. They’re easy to work with, relatively inexpensive — especially considering the costly alternatives of sandblasting or acid washing — and can be used to create endless textures and designs.

Surface retarders work by significantly delaying the set of the surface without disturbing the setting rate and strength gain of the underlying concrete. As a result, the contractor can, after a period of time in which the underlying cement sets, simply power wash or even sweep away the surface, exposing the aggregate.

Concrete workers use surface retarders for three basic reasons: slip resistance, structural integrity and cosmetic appeal.

“Functionally, an exposed aggregate finish provides added traction and slip resistance to a concrete surface,” says Matt Kwiecien, product manager of liquid construction products at Euclid Chemical in Cleveland. “The exposed finishes also reveal specially procured decorative aggregates to add a pleasing look to a concrete surface.”

Practical considerations

Tom Ralston, president of Tom Ralston Concrete in Santa Cruz, California, explains why the larger aggregate tends to settle below the surface in the first place.

“It could be because of gravity and maybe because the vibration of a tamper tool known as a jitterbug forces the heavier aggregate to settle to the bottom,” he says.

Meanwhile, the finer sands stay near the top if too much troweling is done while the surface is still wet or if water has been added for enhanced workability — and that’s where trouble awaits.

“What’s left at the surface is the cream, which is the cement and the finest sands, and it doesn’t have much structural integrity to it,” says Ralston. “If there isn’t enough fine aggregate to act as a binder with the sand and cement, then the surface’s integrity isn’t going to be strong and it can craze, crack and even crumble. You always need a blended amount of aggregate in with the cement.”

Contractors use surface retarders to bring aggregate to the top to solve the challenge and increase the grip.

Ralston has used several brands, but a current favorite is Top-Cast Yellow 15 from Dayton Superior.

Lance Boyer, president of Trademark Concrete Systems, with offices in Southern California, points out another big advantage of chemically retarding over other ways of texturing the pour. “Our customers prefer really fine etches that resemble acid wash, but top surface retarders are safer for workers and better for the environment than acid etching or sandblasting,” says Boyer. “Surface retarders produce a similar result without the use of caustic chemicals, dust, noise, or gasoline or diesel engines. But avoid contact with the skin and use eye and respiratory protection.”

This is especially critical in states such as California, with its tough environmental rules and regulations. Or, for that matter, anytime work is done in populated areas.

“In Los Angeles, if you throw up a cloud of dust you’re definitely going to call attention to yourself,” says Boyer.

“Sandblasting is a more expensive process,” adds Cam Villar, director of marketing and creative at L. M. Scofield in Atlanta. “Sand can’t be recaptured, so once you’ve blasted it out of the wand, it’s gone. You’re just constantly feeding more sand — i.e., more money — at the surface.”

Boyer says that the material cost of a top surface retarder is typically 10 to 15 cents per square foot. There’s added labor costs in the reveal process, but there would be with sandblasting or other finishing processes as well.

A textured look

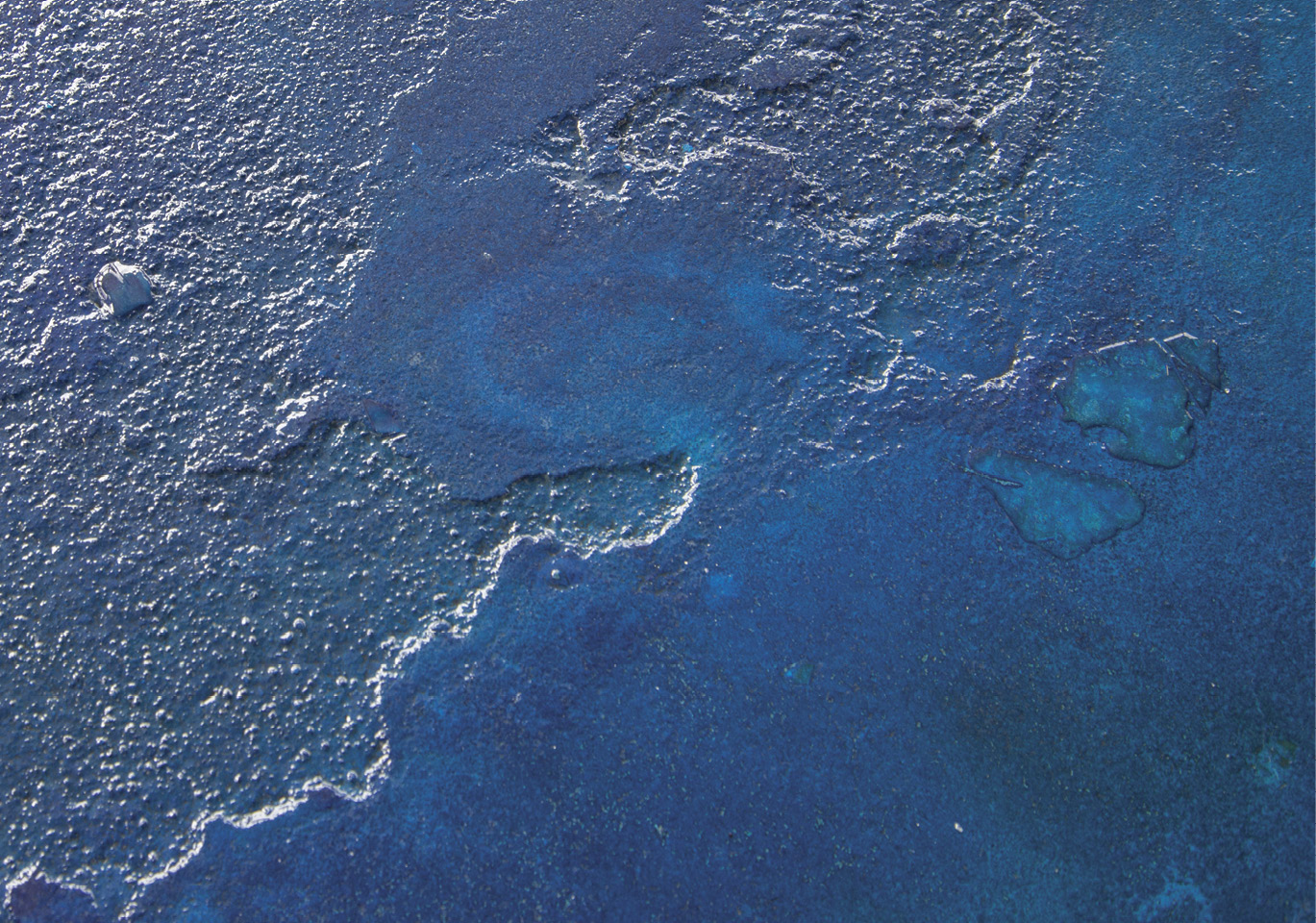

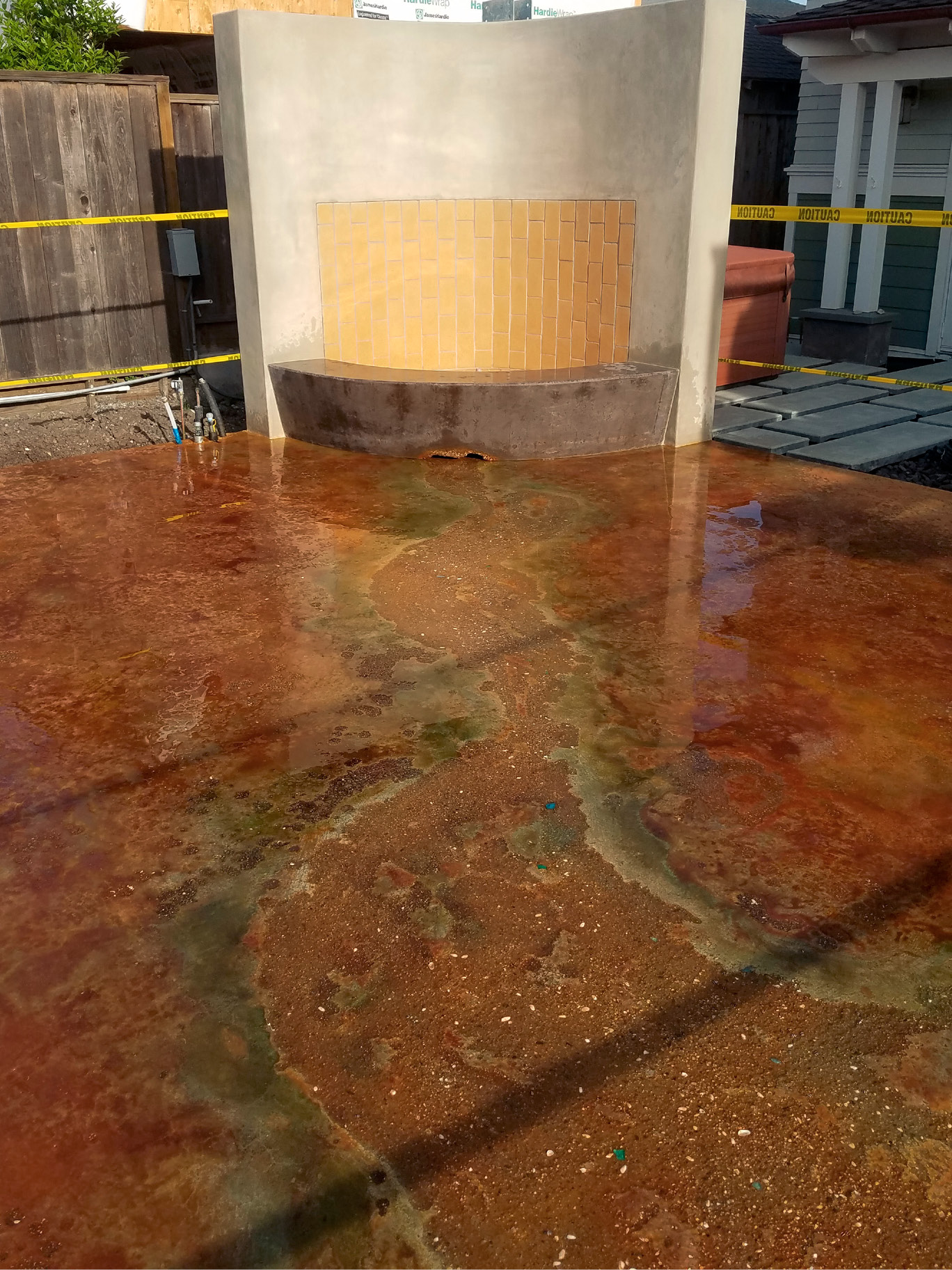

In bringing the aggregate to the surface, retarding results in a rough-hewn, highly textured look, one that’s popular with many of today’s customers.

“It gives concrete an exposed aggregate finish, anywhere between a sandblasted look all the way up to the rough texture of exposed coarse aggregate, depending on the product used,” says Kwiecien. “Retarding depths depend on the concentration and chemical makeup of the active ingredients in the product.”

Euclid Chemical carries three different concrete surface retarders. Concrete Surface Retarder Formula S is for use on flatwork and provides aggregate exposures from 1/8 to 3/16 inch. Concrete Surface Retarder Formula F is for painting on forms for vertical surfaces and provides an etch of up to 1/4 inch deep. Increte EZ Expose is also used for flatwork, but is available in four different grades, providing aggregate exposures from a micro-etch to an inch in depth.

“In Southern California, retarders are commonly used because architects and landscape architects want concrete to look like concrete, not to mimic stone or brick or tile,” says Boyer. “They’re not real big on stamped concrete out here, so the finishes achieved with top surface retarders are probably specified on 90 percent of my jobs, to give them more of a contemporary look.”

The dos and the don’ts

Application of a concrete surface retarder is easy. Boyer simply uses a low-pressure garden hose sprayer. Contractors can also brush on the product. After that, the surface is typically covered in plastic for anywhere from eight to 24 hours, depending on air temperature, humidity and other factors.

California weather can speed up the time frame even more. “If it’s a hot or humid day, it can be washed off in six hours,” says Boyer. “On a more typical day, maybe below 85 degrees, cover the surface with plastic after the retarder has sufficiently hardened and wash it the next day — in 18 or 24 hours.”

What’s left after you’ve hit your surface with the hose or broom is what Boyer refers to as “the muck.” The surface material removed includes retarded hydrated cement paste, fine aggregate and coarse aggregate that can result in alkali wash water and cement solids. “You can’t just wash it into a storm drain,” he says. “But when it dries, it’s a solid paste you can dispose of legally in a trash barrel.”

“We recommend a pretty harsh mix design for retarding,” says Villar. “It should have the highest possible percentage of coarse aggregate, with the lowest possible slump.”

As for the degree of reveal or etch, that depends on the product and the application. “Different products retard up to different depths,” says Kwiecien. “It depends on the concentration and chemical makeup of the active ingredients in the product.”

It takes some degree of experimentation and experience to learn how to properly use surface retarders. Boyer, chairman of ACI Committee C601D – Decorative Concrete Finisher Certification, recommends starting by boning up on your homework. “The ACI has a publication called ‘Placing and Finishing Decorative Concrete Flatwork.’ It’s got an entire chapter on surface retarders that discusses it in depth,” he says.

He also offers one caution: “You’ve only got one shot.”

Retarder can only be used on a newly laid surface. So know what you’re doing before you do it. As with any mix procedure, concrete surface retarder is an art as much as it’s a contractor’s tool.

“Concrete is one building material that’s not made until you get to the job site,” says Villar. “Architects can look at a door handle or a window anywhere and know what they’re getting. But concrete doesn’t work that way.”

And neither does surface retarder. But once you gain expertise, you can use it like an artist — to provide your customers with a finished product that has the look and the feel they want at a cost they can afford.