Anything worth doing is worth doing right. Don’t cut corners and expect quality results. These may sound like clichés designed to get folks to toe the line but more often than not, I’ve found them absolutely true. In the same way that you get what you pay for, you get out of something what you put into it. The same is true for removing acrylic sealer from concrete.

For example, suppose a backyard concrete patio is ready for a facelift. The acrylic sealer applied years ago is worn out and the surface is blistered, chalky and cloudy. The impression it will leave on guests is not the impression wanted. So what’s the remedy? Technically, you could just reapply a sealer and hope for the best. But if you want to do it right, you start by prepping the surface for a new sealer by stripping away the old sealer. The results you see on the surface are only as good as the foundation.

Off with the old

There are several common approaches to removing acrylic sealer from concrete and none of them are easy. Each of these options will work — eventually — but there are pros and cons to weigh.

Hazardous solvents. A solvent like xylene is effective at removing acrylic from concrete. It dissolves (“softens”) the acrylic and allows for removal. However, solvents such as xylene have a harsh smell, are flammable, dangerous for your skin, and shouldn’t be used around children, pets and plants. Most importantly, these types of solvents are not EPA compliant for use in this way.

Stripper + pressure washers. A compliant floor coating stripper combined with a power washer can blast away old acrylic pretty effectively. This method works but typically requires significant “elbow grease” to soften the acrylic. The step of removing the softened acrylic by pressure washing requires significant prep work to protect landscaping, siding and other surfaces from splatter of the softened acrylic and over-spray of the stripper that could strip other surfaces. Pressure washing without the benefit of a stripper is generally not very effective.

Sandblasting or grinding. Aggressive techniques such as these may get the job done but it will often compromise the original surface and aesthetics of the concrete. It also is laborious, creates a mess and requires significant cleanup.

So, what’s the best option for removing worn-out acrylic sealer, particularly in a confined space like a backyard patio? Biodegradable blanket stripper treatments are a great option in this type of situation.

Blanket benefits

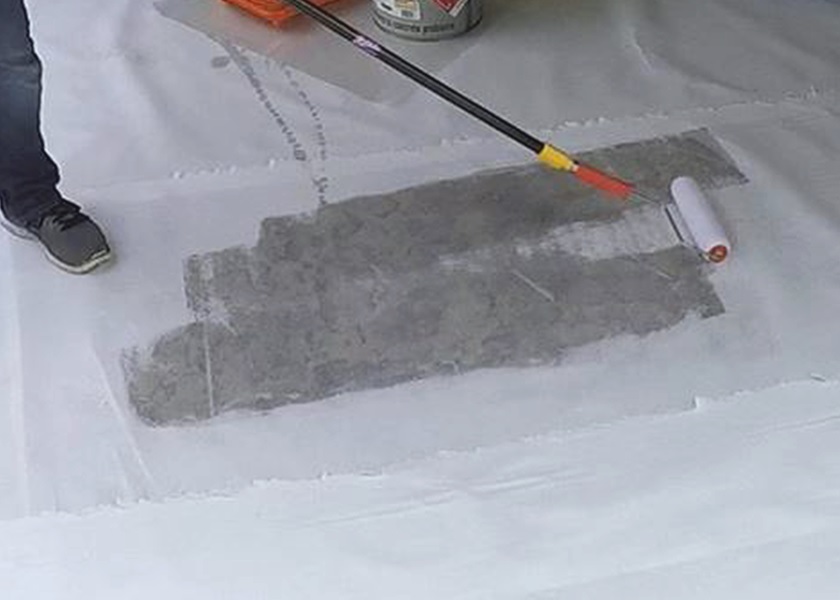

This stripper method is easy to use, safe and highly effective. Sweep the surface clean and remove all debris. Cover your affected surfaces with a specialized biodegradable cellulose blanket and apply a biodegradable stripper right over the top. Use a brush for edges and small spaces, and a 3/8-inch nap paint roller for the larger surface areas. Spread the solvent on evenly until the blanket is saturated. Let the blanket dry completely, then simply pull it up and throw it away.

Tips for optimal results:

- Make sure the surface is dry for 24-48 hours before using a blanket stripper.

- These biodegradable solvents work best between 50 and 85 degrees F.

- Application during low sun angles (morning or evening) requires less product and produces better results.

- Don’t forget the valleys, joints and ridges. Keep rolling until the whole blanket becomes translucent and the concrete is visible through the fabric.

- Dry time of the biodegradable solvents is variable depending on weather conditions, but typical dry time is between two and six hours.

- Allow at least 24 hours after stripping before applying a coating or sealer.

Not only is this method easy, fast and effective, it’s also environmentally friendly when you choose biodegradable materials. The blanket, instead of the nearby soil, absorbs the stripped chemicals. The blanket system may not remove multiple sealer coats in one application and may require additional applications for complete removal.

On with the new

You’ve successfully removed the faded, delaminated sealer from your surface and you’re ready to reseal. Acrylic sealers are easy to apply and economical. They create a thin protective film that gives concrete a wet look. Acrylic sealers are available in solvent- and water-based formulas.

Questions from Concrete Decor Readers

Question

I need to strip a xylene-based acrylic sealer from a residential, acid-stained, interior concrete floor (no texture). I can’t use a pressure washer. Will this system work for that? Will I need to restain the floor? Can I go back with a polyurethane sealer?

Answer from Concrete Decor

The Deco-Peel product is a great option for removing acrylic-based sealer. Make sure to adequately wet the fabric. If the surface has a more aggressive texture, the manufacturer recommends pouring the stripper onto the fabric and moving it around with a roller.

After the stripping application, you may also consider wetting the surface with a light solution of Simple Green and scrubbing. Then vacuum up any residue. This helps to ensure that the sealer has been adequately removed so that new coloring applications absorb and bond to the cleaned surfaces.

Question

I have a state-inspected kitchen which has colored concrete that we had sprayed one coat of Everclear acrylic sealer on. Apparently, I didn’t do my research well enough and thought that Everclear would be hard enough to protect from grease splatters which is not the case. I now have spots all over in front of the ovens and stoves. I would like to know how to remove the thin coat of sealer in order to put on an impact-protectant sealer.

Answer from Concrete Decor

Thanks for sharing your questions with us at Concrete Decor.

You can strip the Everclear acrylic sealer with a citrus-based stripper. The manufacturer of that product calls for a product called Euco Clean and Strip, but I think you can find a similar product at your local hardware or paint store.

I stripped my concrete countertops last summer with Jasco paint remover. Then I followed that with a mild washing of the countertops before lightly sanding to remove any remaining stripper and rough spots. I used the Impact product in a satin finish and we’re very happy with the result.

The Impact product is also available in smaller quantities called I-Tech.