Imagine the convenience and versatility of decorative concrete finishes that you can apply to either walls or floors.

Actually, it’s not a matter for the imagination. Such decorative finishes already exist.

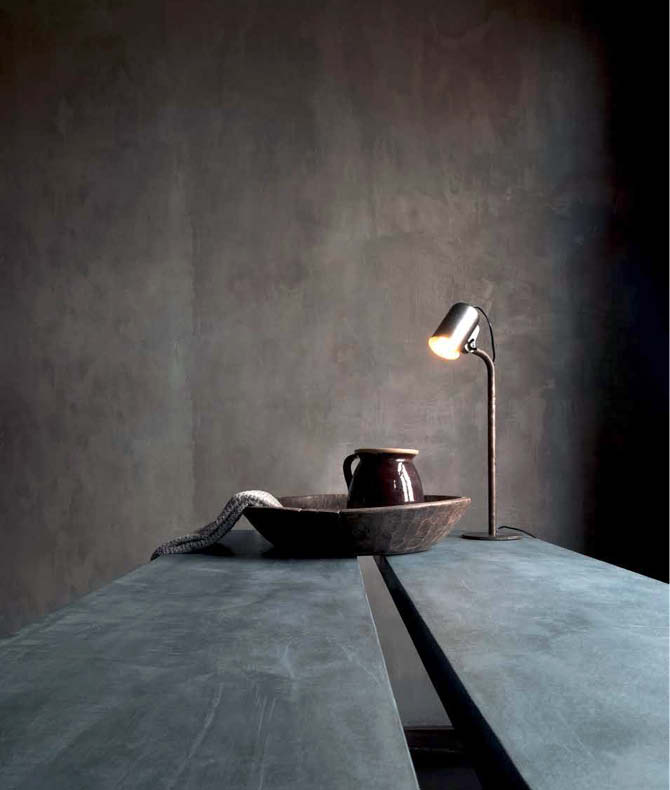

A more striking facet of these materials, however, may well be their role in enhancing visual effects in certain architectural settings — spaces where “less is more” in terms of color or mind-bending decorative patterns.

Such is the proposition put forth by Ideal Work, an Italian-based developer of cementitious coatings and other decorative finishes. And Exhibit A in Ideal Work’s case for this concept is museum space.

“Museum buildings, like art galleries, have to act as a blank backdrop that show (art and other items on display) at their best, making them easy to follow, access and comprehend,” Ideal Work notes in marketing literature highlighting museum-space applications of its Nuvolato Architop, Microtopping and Lixio products.

Although you can’t apply it to vertical surfaces, Ideal’s Nuvolato Architop and Lixio are good candidates for seamless surfaces or more traditional treatments on floors. You can use Nuvolato Architop to create polished floors over existing or new floors, with a “minimal depth” application process. And Lixio delivers a “more traditional finish” for existing floors, similar to terrazzo, with exposed aggregate in various sizes and colors.

Microtopping by IdealWorks

Ideal’s versatile Microtopping product can be used to create matching, seamless floor and wall surfaces in new builds and refurbishments. With a nominal thickness of just 3 mm, it provides a “perfect, almost anonymous,” background,” according to Ideal Work.

“When viewing real pieces of history or art, no one wants to be distracted by ‘clever’ architecture, bright colours and heavy textures,” notes Giovanni Fonte Basso, communication manager.

Going micro

“Microtopping is elegant, versatile, metropolitan and minimalist,” Basso says. The material has been used at Memorial Centre Lipa Remembers museum in Lipa, Croatia; the Teseum Museum in Tongeren, Belgium; and the renowned Palazzo Ducale (Doge’s Palace), one of the main landmarks in Venice.

The company spokesman says you can use the cementitious material to renew existing surfaces of various types — concrete, self-leveling, ceramic, wood or others — without removing these substrates. The product is described as highly resistant to weather change, easy to clean and quick to install.

Ideal Work uses the term “continuous space” to describe the decorative effect created with the microcement in a minimal modern environment where the surface stands out as the main feature, or a “classic, rustic or vintage environment where it completes the style with refined discretion.”

The minimalist approach, essentially.

Minimalism, American edition

But before all the credit for this minimalist wave goes to Ideal Work and other makers and users of these kinds of finishes in Europe, American contractors such as Dominick Cardone of Diversified Decorative Finishes Inc. offer a dissent.

At least on the East Coast, minimalism, as opposed to polychromatic excess, is very much in play, says Cardone, who’s based in Brooklyn, New York. Cardone frequently uses materials from Duraamen Engineered Products Inc., including the company’s Skraffino concrete microtopping, in his decorative endeavors.

Cardone cites a recent project of his — a high-end residential building lobby in New York City — as an example of the minimalism approach, East Coast edition. He used the Skraffino microtopping in a warm gray tone to produce a muted, neutral background for the decorative pieces and furnishings that the project designer made prominent in the lobby space.

On the walls, composed of sheetrock, Cardone trowel-applied two coats of Skraffino. He opted for a 50-50 mix of the fine and superfine grades of the microtopping, using the white base color. The first coat dried overnight. They then sanded and cleaned it prior to applying the second coat.

Cardone used a mix of gray and brown colors added to the white base color to produce what he calls a “warm gray.” An acrylic clear sealer completed the treatment.

The use of Skraffino microtopping

On the new concrete floor, Cardone also used the Skraffino microtopping. Here, he started with grinding and minor repairs, then applied Duraamen’s Param 5500 self-leveling underlayment — a cementitious calcium aluminate material.

This provided a “beautiful canvas,” he says. Following dry, he mop-applied the Duraamen CP1000 acrylic dispersion, which also serves as the copolymer component of the Skraffino system, as a primer. The Skraffino was trowel-applied in two coats, with a screening in between using a floor polisher. The first coat was done with the fine grade of the microtopping. Then they followed it with a fine-superfine mix for the topcoat.

Cardone completed the work with another sanding, an application of a 100-percent solids clear epoxy, another sanding, and finally an application of a clear urethane sealer.

Sealer performance looms large in these kinds of floor applications, Cardone emphasizes. Here, “It’s made to stand up to traffic,” he says.

A Duraamen spokesman says Skraffino is specified where designers and owners opt for seamless concrete walls. Contemporary high-rise buildings, lofts and apartments are typical candidates for these kinds of microcement applications.

Duraamen recently rolled out another product, “Arapido,” a sprayable microtopping for concrete designed for quick application to large areas.

The ‘gallery’ effect

Cardone says the monolithic effect of this microtopping application on floors and walls produces a “simple, clean, elegant” look that places the spotlight on other design elements — a darker, leather-clad wall recess in one area and wood paneling in another, and stone and concrete elsewhere. Other furnishings complete the picture.

“In a gallery you want the art or exhibits to pop,” he says. “In retail, you want the product to be the stand-out.” Here, the furnishings and architectural elements take center stage.

This eclectic approach also tends to give the space more depth and warmth, he says.

The microtopping can produce a varied surface texture that adds depth, Cardone says, with the use of the three different grades and a specific trowel technique.

“It can go from rough to highly burnished, so it’s up to the designer and the installer.” He applies the term “consistently inconsistent” to a finish that exhibits variation and depth. Lighting also plays a key role in the resulting impression.

The expanding microcement palette

A new entry in the microcement wall- and floor-treatment portfolio is an import from Europe — CimentArt. The product line, from Spain, has come ashore in Florida, where a new company, CimentArt Florida, has set foot on North America as the U.S. distributor.

“We will be setting up a distribution network,” says John Miles, managing director of CimentArt Florida in Clearwater. A news announcement for the product says CimentArt won awards in Spain for quality and environmental friendliness.

You can apply the microcement to just about any surface and space, Miles says. He cites tile, showers, countertops, wood, plaster and plasterboard, concrete, ceramic and porcelain as options. You should apply it at a maximum thickness of 2 mm. Doing this creates a continuous coating with marbling effects and no joints. Amazingly the various layers of the base, topcoat, sealer and two-part varnish are also strongest the thinner they are, Miles notes. The microcement products also waterproof the surfaces.

The product line is available in a range of colors and includes products to achieve decorative, smooth or stone-like finishes, as well as Oxide, Solid Color, Metallic, Aqua Quartz and Aqua finishes. The product portfolio also includes a mixing resin for the microcement formulas, polyurethane and acrylic sealers, a metallic sealer for “high decoration” with 10 different metallic finishes and an acrylic primer, among others.

Ardex SD-M

Stateside, U.S.-based Ardex Americas makes its case in the wall/floor finish arena with Ardex SD-M. This product is a trowelable cementitious microtopping for resurfacing interior concrete and terrazzo. You can also use it on ceramic, porcelain and quarry tile.

Though marketed primarily for horizontal surfaces, Ardex notes the microtopping is often specified and used by designers, contractors and other installers on walls. Here, its impact and abrasion resistance and also its smooth, creamy consistency make for stellar performance. You can apply it in an artistic fashion to emulate a rustic look. You could also apply it as a stucco or knock-down finish.

In vertical applications, contractors use the microtopping to create a “unique aesthetic” on fireplace faces. They also use this to accent walls and backsplashes in retail, residential, commercial and hospitality settings.

Craig Morris is Ardex Americas business development manager for finished surfaces. He advises that for vertical applications, specifiers and users should contact the company’s technical department for recommendations and other considerations. He says this is particularly true where you will be applying the microtopping over gypsum-based surfaces such as drywall.

Dominick Cardone was also one of the featured artisans at Decorative Concrete LIVE! at the 2020 World of Concrete.