Reactive staining on vertical concrete surfaces is not that common — yet. But according to Steve Schmid, president of Stone Touch Inc. in Salt Lake City, it’s starting to catch on

Schmid is a vertical stain veteran. He has stained a 22-foot-high, 38,000-square-foot retaining wall for a ritzy residential development in Jackson Hole, Wyo.; an 80,000-square-foot tilt-up office building, also in Jackson Hole; three bridges in Salt Lake City; and a library in St. George, Utah. “In an area like Jackson, painting looks so artificial in such a beautiful setting,” he says. “There are quite a few stained vertical surfaces up there.”

The more walls he stains, the more requests he gets. “They see a job we’ve done and they want the same thing,” he says. “As people see how it’s a viable option and that they don’t have to repaint it, it kind of catches on.”

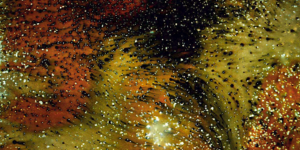

Spraying stain onto vertical surfaces can yield remarkable results. Just ask Kemiko Concrete Products president Barbara Sargent. One of the company’s signature jobs was completed in 1953 on the walls of Jackson Lake Lodge in Grand Teton National Park. Even today, the building shimmers with “the colors of the Grand Canyon,” Sargent says.

Applying reactive stain to a vertical concrete surface is not all that different from staining a floor — concrete is still concrete and stain is still stain. But prior knowledge of a few common problems that crop up when the process is tilted up can help save some anguish later on.

Potential problems

Santa Cruz, Calif., contractor Tom Ralston used extreme measures last winter in New York state when staining 36,000 square feet of wall, 35 feet to 40 feet high. Workers rode lifts to power wash the walls and applied stain with backpack power sprayers. “We tackled this problem with unique weaponry,” Ralston says.

Staining vertically poses a unique set of problems. On a vertical job, some of the slab is well out of reach, which makes achieving consistency more difficult. Getting workers and equipment to the top of the wall is not easy, and gravity causes the stain to run and streak.

Finally, there’s the acid mist. To avoid drips, the stain must be applied as several coats of a light, fine mist. At the top of a high wall, wind will catch the hydrochloric acid fog and distribute it onto everything from windows and sidewalks to the skin of employees. “You can actually develop esophageal problems,” Ralston says. “It’s ‘water in the lungs.’ It can be a real problem.”

Another issue on the New York job was temperature, particularly as they were working in November. “Acid stain doesn’t seem to take as well if the temperature gets down to freezing,” Ralston says. “All bets are off.”

Schmid of Stone Touch says streaking is the single biggest problem he faces on vertical surfaces. A rolling bead of stain can do serious damage to a high-end finish. “It’s really difficult to keep it from running,” he says.

However, he has developed a few techniques that keep drips and runs to a minimum. Like Ralston, he applies the spray in a fine mist with a light coat, making several passes. “Using a fine mist like that, the wind can carry it forever,” he says. “It’s not pleasant. Stuck up on a lift, you can’t get away from it. You have to have full protective gear on, head to toe.”

It’s best to have the staining completed before other parts of the building are put in place, Schmid says. “The stain is going to etch any glass, metal or plastic. It will etch stucco. It will stain caulking.”

It’s best to have the staining completed before other parts of the building are put in place, Schmid says. “The stain is going to etch any glass, metal or plastic. It will etch stucco. It will stain caulking.”

Conditions such as direct sunlight and rain will also influence how well the job goes, Schmid says. Hot or cold temperatures can alter the reaction time and even change the shade of the stain. “It’s not a huge effect, but it’s visible enough to notice.”

If staining two sides of a building, Schmid does one side in the morning and one in the afternoon to maintain consistency in every variable.

Application techniques

As with any concrete job, staining a vertical surface begins with proper prep work. Sargent of Kemiko says for many walls, a pressure wash to remove weathering will suffice. But Scott Thome, director of product surfaces for L.M. Scofield Co., recommends starting with a mechanical scour, such as sandblasting or scarifying. “For all stain applications, the substrate must be open to absorb the stain and durable enough to accept and hold the sealer for the intended use,” he says. “When pressure-washing a concrete substrate you are mainly cleaning the surface and not mechanically opening the pore structure.”

Form release agent or tilt-up bondbreaker residue is a concern, which is why Nox-Crete Products Group recommends pretreating the wall with a solution of TSP in water followed by pressure washing. Schmid recommends sandblasting tilt-up walls beforehand to remove excess form-release agent and better protect the surface against runs.

When it comes to application, contractors lean toward spraying, although some may use a sponge or foam brush to achieve a special effect. Kemiko recommends an all-plastic handheld garden sprayer. “Our product is a very mild hydrochloric acid. It’s going to react with anything that’s metal,” Sargent says.

The creative muse might influence the choice between metal and plastic spray equipment, Thome says. “We read that only plastic should be used in sprayers, brooms and other equipment when applying acid-based stains. That is true if you do not want to incorporate metal impurities into your project. But there are contractors that intentionally use a copper wand on a sprayer to obtain a certain look.

“Is this a good application practice? Not really,” he adds. “It can be dangerous, and when working with acid-based stains, you need to be aware of safety.”

Fix the drips

Fix the drips

Manufacturers are also eager to address the run factor. “It is best to practice your application techniques in advance of performing any work for a paying customer,” says Michael Linn, president of Nox-Crete Products Group. “Removing run marks is not easily accomplished.”

The best way to fix drips when they do occur is to catch them with a brush or something absorbent, such as a C-sponge.

A scrub afterwards reduces surface tension, making a stain more uniform, particularly on a tighter vertical slab, Thome says. Diluting an acid-based stain with water will reduce reactivity, which may also minimize streaking, he says.

To further minimize the run problem, many contractors start at the bottom. “Dilute the acid-based stain, pre-wet the wall, start the application from the bottom and work your way up,” Thome says. “With water borne reactive stain, if you obtain rundown, you are applying the material too heavy.”

Nox-Crete recommends applying acid stain with a hand pump sprayer, working from the bottom up with a 3-inch to 5-inch rundown, immediately followed by scrubbing with a brush. “Several light applications generally provide a more uniform appearance with minimal run marks,” Linn says. “Scrubbing the acid stain immediately after application removes acid reaction products from the surface of the concrete, allowing uniform and deeper penetration of the acid stain.”

After application

How big can you go? “There’s no limit to space if you have control of the job, if you have people who help control dripping,” Sargent says.

Joints and angle changes in the structure can be used to break up the space. Nox-Crete recommends applying its acid stain to small, workable areas, Linn says. “For example, start the application at a corner and work to a feature strip, rustication strip or expansion joint wherever possible, to minimize color or shade differences.”

The next step is letting the stain dry. If the job is outdoors, heat and sunlight will affect how the stain reacts with the concrete, so whenever possible, work in the shade. “On any stain project with a product that produces a chemical reaction, you do not want the product to dry out extremely fast,” Thome says. “Keeping sunlight to a minimum will minimize premature drying of the material. Also, wind will cause the stain to dry before the full chemical reaction can take place. For acid-based stains I would recommend predampening the surface with cold water prior to application. This will not only cool the wall but also help minimize streaking.”

When it comes to sealing a stained wall, most sealers will work fine — as long as the customer has approved the final look with a mock-up, Thome says. “There is a zoo that is using a potassium silicate over an acid-based stain to develop a higher abrasion resistance surface on their rockscapes. The appearance is what they are looking for, and it is lasting longer than a typical sealer.”

There are a few sealers that actually diffuse ultraviolet light to protect the color from fading, Thome says. “These are very high-performance acrylic-modified urethanes, so the price will be higher, but the performance is better than many of the other options.”

When a stain job is intended to complement an outdoor setting, flat and matte sealers are better fits than glossy sealers, which can look shiny and fake. “The high gloss look in many markets is the thing of the past,” Thome says.

When a stain job is intended to complement an outdoor setting, flat and matte sealers are better fits than glossy sealers, which can look shiny and fake. “The high gloss look in many markets is the thing of the past,” Thome says.

But the appeal of matte finishes is partly geographical, he says. Gloss is still popular in big cities such as Philadelphia, New York City and Chicago. “Shine to some people means expensive. It comes down to, do you want it to look rich or do you want it to look like a natural piece of stone?”

To seal vertical acid-stained concrete surfaces with the wet look, use two coats of either a water-based or solvent-based clear acrylic sealer, Linn says. “The acrylic sealer gives acid-stained concrete the ‘wet look’ and brings out all the shades of color.”

On Schmid’s tilt-up office building job, he used glossy solvent-based acrylic on the bottom half of the walls and silicone-based natural look sealer on the top. The glossy sealer gave the walls more protection near the ground, he says. On the other hand, he did not seal the huge retaining wall project at all. “Stain itself really doesn’t need anything to protect it,” he says. “But some people feel better if it’s sealed.”

There is one more factor, possibly the thorniest when it comes to acid stains: cleanup.

The acid must be neutralized. Nox-Crete recommends neutralizing the acid residue with a solution of sodium bicarbonate and water. But there’s more: The heavy metals in many acid stains are also contaminants.

“The heavy metals that actually produce the color are what should be the real concern,” Thome says. “If these metals get into the groundwater they will contaminate the water system. They are much more hazardous than the acid in the stain. All of the residue that is to be removed after the application of the stain must be captured, treated and disposed of according to local regulations.”

Waterborne reactive stains don’t leave behind any residue to be removed, he notes. “Once waterborne reactive stains have been applied to a concrete substrate they will remain there, and no washing is necessary. This reduces the contractor’s liability on the project.”