True or false? When using a black pigment to integrally color concrete, black is black and that’s that.

Answer: Absolutely false.

Black is widely used in the concrete industry. It can be mixed to darken other pigments, and it can be used alone to make light grays, dark grays or straight black.

It’s commonly used in driveways — and especially in gas stations — because it hides oil stains and grime. It’s sometimes used in highways and runways because black absorbs heat and discourages ice. In decorative concrete, integral black with a silver release is a popular combination.

“Black is easily one of our top five colors out of our 40 standard colors,” says Nick Paris, vice president of marketing for Davis Colors, the Los Angeles-based color manufacturer.

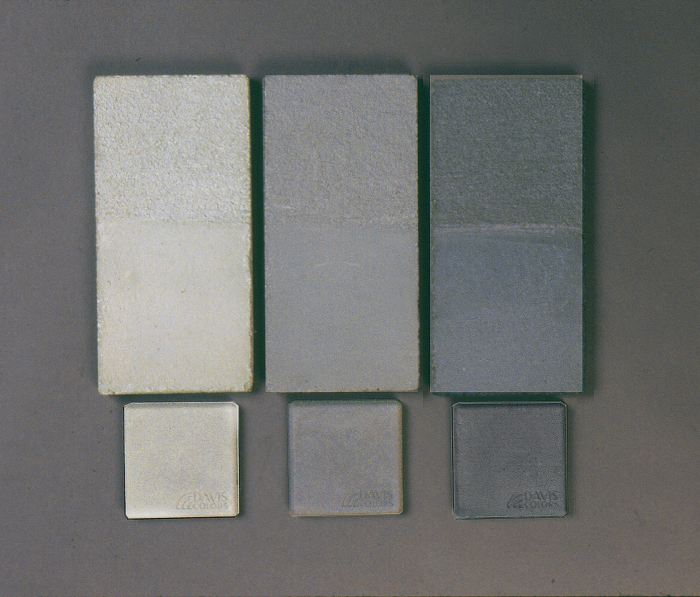

Black pigment for integral coloring comes in two forms, one made from iron oxide and one made from carbon.

Iron-oxide black is the most commonly used in black concrete, Paris says. “Most people find it black enough,” he says. “But occasionally someone wants a super-dark black, and then we recommend carbon black. With carbon black it’s possible to get a jet-black, like a bowling-ball black. Iron oxide just won’t get that black.”

Carbon creates the blacker black. It’s also more economical. But it can affect air entrainment, and it can weather out of concrete over time. So just any black won’t necessarily do.

Carbon black also has a bluish tinge to it that some people prefer to iron-oxide black’s brownish tinge. “But then you’re really splitting hairs,” Paris says.

Carbon black has two to five times the tinting strength as iron-oxide black, so a little carbon black goes a long way. This makes carbon black the more economical of the two. But bargain shoppers beware: there are other costs.

Weather effects

In freeze-thaw regions, the loss of air entrainment becomes an issue. Air entraining admixtures, used to protect concrete against cracking in cold climates, introduce microscopic air bubbles that allow water molecules in the concrete to expand when freezing without causing damage.

Some carbon black pigments absorb air entraining admixtures, rendering them useless.

“When you add carbon black your air content is going to decrease,” says Terry Collins, a concrete construction engineer with the Portland Cement Association. “If you increase your air entrainment dosage, you should be able to bring your air entrainment back up to the same level. However, air entraining agents aren’t free, so that may increase the cost of the concrete mixture. And you’re going to have to spend time figuring out what the right dosage is going to be.”

Another way to compensate for carbon black’s appetite for air entrainment agents is to use a carbon black pigment formulated specifically to leave entraining admixtures alone. Davis Colors’ liquid form of carbon black is such a pigment, though the company’s powdered and granular forms of carbon black are not.

The loss of air entrainment can be avoided altogether by going with iron-oxide black for exterior concrete in icy climes.

“If you’re in a freeze-thaw cycling area, and you want less potential for fluctuations in the air content coming into play and possibly producing concrete in some areas that isn’t as durable as others, you might want to shy away from carbon black,” Collins says.

Additional concerns

Another big drawback to carbon black is that it can leach out of concrete when exposed to the weather.

Where iron oxide pigments bond with portland cement and become a permanent part of the concrete matrix, carbon black does not. As water evaporates from the surface of concrete colored with carbon black, it can draw out the carbon, causing the concrete to fade. Sealing the concrete can prevent this, but the you must reapply sealant periodically.

Surprisingly, contractors use carbon black frequently in swimming pool plaster. Pool makers like it for the economy. It works because in a full swimming pool, the black plaster isn’t subject to evaporation. But it’s a different story if the pool’s left empty.

A difference of opinion

Richard Solomon, president of Solomon Colors, an Illinois-based color manufacturer, doesn’t care for carbon black at all. Although his company offers a carbon black to satisfy demand, it won’t promote the pigment or even list it on the company’s color cards.

“Carbon black is great for putting into automobile tires, but not concrete,” Solomon says.

“The pigment itself is a good pigment, but the bond of the cement isn’t tight enough to hold it,” he says. “It should never be used outdoors. I’ve been doing this for too many years, and I haven’t seen an exterior job yet where it won’t weather out.”

Sure, sealants will prevent carbon black concrete from weathering, Solomon says. “But the problem is it needs to be kept sealed, and you and I both know that doesn’t happen.”

On rare occasions, carbon black is chosen precisely because of its weathering characteristic. Nick Paris at Davis Colors sees such jobs once in a while.

“They’re usually cities on the East Coast doing sidewalks,” he says. “They use just enough carbon black to make the concrete kind of off-white, to make the new concrete look like old, dirty concrete when they patch a sidewalk. Eventually it weathers out and everything still matches.”

Regardless of whether you use iron oxide or carbon pigments, black concrete (and any other darkly-colored concrete) will highlight efflorescence. Efflorescence is the white powdery deposits that sometimes appear on new concrete as salts dissolve. Dry-brushing typically takes it right off, and chemical removers are available for stubborn cases.

Efflorescence might go unnoticed on uncolored concrete, but it’s hard to miss on black.