According to Gizmag, scientists at the Swiss Federal Laboratories for Materials Science and Technology (EMPA) have added polypropylene (PP) fiber to a concrete mix. When the concrete is exposed to high heat, as in a fire, the fibers burn away. The resulting holes that are left behind create a network of canals, of sorts, for the water vapor to escape. This trick prevents pressure from building inside the concrete, making it more fire-proof.

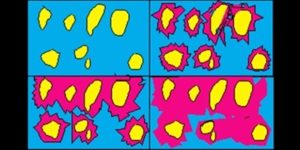

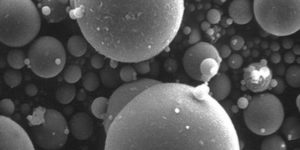

The researchers made a series of thin concrete walls which were mixed with polypropylene fiber. Some of the walls also contained a synthetic material called super absorbing polymer (SAP), which is able to absorb many times its own weight in water. When the SAP is soaked in water before being applied, it swells up to several times its dry volume. As the concrete sets, the water is drawn out of the SAP and into the cement, which then causes the SAP to shrink and leave behind hollow spaces inside. These spaces and the other hollow spaces left by the bruned up polypropylene fibers create a network of channels allowing the concrete to release the water vapor.

The team exposed the concrete walls to temperatures up to 1,852 ° F. After 90 minutes, the SAP-dosed concrete did show some minor cracking, but the most severe fire damage (severe chipping and flaking) only occurred in the SAP-free concrete.

The laboratory has applied for a patent for its new technology.