It was painfully obvious from the contractor’s voice that something was wrong. No passive small talk about family. No “How’s the weather?” Just straight conversation cutting to the heart of the problem at hand. His voice hastened as he got to the point where the acid stain didn’t react to the concrete surface on a rather large, fast-track commercial project. In fact, not only did the first pass of stain not react but neither did the second coat. My mind raced for the proverbial silver lining, but I had nothing. That’s when I asked the one question to which I already knew the answer.

Today’s lesson is one each decorative concrete professional must heed: Creating the perfect project sample is the path to your artistic future. The contractor we are describing today trusted an acid stain color chart over an on-site sample on a real-life concrete canvas. The price for such inaction is one he will talk about for decades.

There are several key steps comprising every successful decorative concrete project. The first step, at least after properly selling a project, is to create a perfect sample that accurately represents the end result of your time and effort. Now, for the record, the perfect sample mustn’t be confused with perfectionism or flawlessness. The perfect sample is nothing more than the cornerstone of accuracy on which to establish a level of expectations. In my opinion, a flawless finished project rarely happens. On the other hand, a sloppy sample expresses a lack of organization and, ultimately, predicts a less-than-acceptable finished project.

There are three key components, or steps, to creating the perfect decorative concrete sample. Perform all three correctly and you increase the odds to nearly 100 percent of matching your customer’s expectations. A customer with fulfilled expectations is most likely to talk up your contracting services. Skip one step and the odds decrease to around 70 percent, or possibly less. This means at least one third of your customers will have nothing positive to say about their experience — or you.

Step One: Ask what they like

The first step is more of a fact-finding mission than anything else. The goal is to establish likes, dislikes, taste, distaste and anything else that can help forge a connection with your decision-maker. This process can take 30 seconds of conversation or months of coordinated effort. The only way to find out how long this step will take is to initiate conversation by asking questions that pertain to your customer’s personal preference. This step does not require anything tangible to hold, show or display.

Remember, this is not about you and your successes. This is entirely about discovering what your customer likes and then what it will take to match their expectations from start to finish.

Step Two: Show options

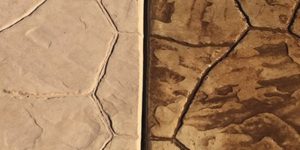

The second step is nothing more than dumping all information from step one into a bowl and then stirring it together. The result should be combinations of color, texture, pattern and design necessary to create personalized samples of what it will take to meet your customer’s expectations. There is no reason to create, or show, anything other than samples geared toward your customer’s taste. This is not the time to introduce a new color or technique that would look “really cool” on their concrete countertop. Save the new technique for the customer willing to accept the surprise of something out-of-the-box creative.

This second step can, in some cases, take place moments after the first step. Some individuals will ask for pictures or color charts within minutes of your first meeting, and this is okay. At this point, remember to not overwhelm your customer with too many choices, charts or samples. I recommend keeping all options geared toward their personal taste according to step one.

Step Three: Clarify expectations

The last step is about acceptance more than anything else. Haste and anticipation often cause some decorative artists to power through step three. I understand — the owners are excited to see their project become reality — but each tiny relevant detail of the sample should be discussed. Are they expecting a solid color or something translucent? Do they comprehend that some variations in color should be expected? Do they realize the work in process will not always look like the finished product will?

At this point there is nothing left to chance. Each step taken to create the sample must be practiced over the entire project, everything from batch materials and consistency to surface preparation. The process used to create the sample now becomes the project’s specifications. All three steps described above will become integrated into each project, all in their natural order.