Concrete is most often thought of as the material of choice for driveways, basement walls, curbs and gutters, and roadways. There is not another material on earth more durable, strong, and cost effective.

The material is being looked at through a different set of eyes, however. Concrete is being looked at by a growing group of architects, designers, contractors, and most importantly, buyers. All of these groups are clamoring for these concrete products and floors.

Concrete is being used as a final interior flooring surface in direct competition with wood, tile, marble, and slate. Concrete surfaces can be stained, scored, sandblasted, overlayed and stamped — or a combination of the above. While concrete is custom and beautiful, it is also clean. According to the American Lung Association, 26 million Americans have been diagnosed with asthma in their lifetime. Dirt that accumulates in carpet is a large contributor to asthma problems.

Got cold feet?

For many years concrete was not considered for some interior surfaces due to it being a cold surface,. Although concrete is no colder than tile. Today, buyers are opting for decorative concrete and in many cases handling the

cold floor issue by using radiant floor heating systems. These systems heat the slab either by hydronic or electrical means, providing optimal comfort since it is warmest by the floor and gradually cools as the distance from the floor increases. Conversely, forced air heating systems deliver heat at the ceiling line — where it is of the least use.

Your floor is your life

Some craftsmen are literally creating decorative concrete art on floors for their customers. David Pettigrew of Diamond D Concrete in Watsonville, CA has created a floor at the 6000 square foot Griffin residence in La Honda, CA. Pettigrew and his wife Catherine drew sketches for the floor designs and the impressed Mark Griffin responded,”You can do this with the concrete?”Pettigrew’s crew of five men spent three days just scoring the designs into the concrete floors. Then, it was a six-week process to color the floor. Dave utilized four treatments on this project: Micro topping, acid-etch stain, Con Color, and Plate-All — which is molten metal on concrete.

Gary Breaux of Surface Effects in Lake Charles, LA provides custom painted floors that create the look of marble, stone, and slate. He can create a tiled appearance without seams or lines, providing the owner with a smooth low maintenance floor. Breaux uses epoxy resins for base and color coats. Then he applies a non-yellowing urethane as a durable top coating finish.

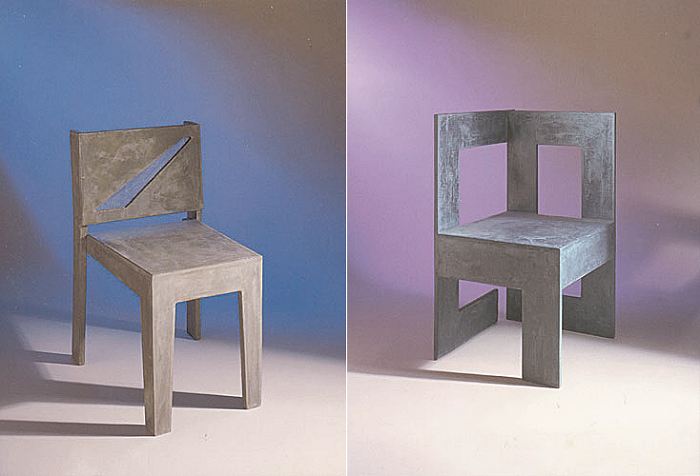

Besides flooring, consumers are also using concrete for countertops, tub surrounds, sinks, fireplace surrounds, wall tiles, and even furniture. Steve Rosenblatt of Sonoma Cast Stone has 44 dealers throughout the United States who sell products such as his”Wave Sink”, which won an award from the National Kitchen and Bath Association. He also makes custom pavers, tub surrounds, and a variety of other concrete products.

Growth of Business

Gary Simpson of Kaldari does a brisk business selling his concrete furniture at the Festival of Arts annual event in Laguna Beach. Simpson also manufacturers concrete countertops. Additionally, he does concrete staining for floors in the Los Angeles and Orange County area of Southern California.

The growth of concrete applications seems to have taken on a self-fulfilling aspect. As designers and consumers learn of these products on the Internet, in print magazines, or see them on floors or countertops in public places — they want more of the products. As demand grows — so does the amount of creativity and diversity of offerings from concrete trade’s people and other craftsman from outside the concrete industry.

In some cases it is artists or those with architectural backgrounds or other building experience turning to concrete as their medium, versus concrete contractors turning into artists. Mark Rogero of Concreteworks Studio in Oakland, CA, for instance, is a trained architect. Fu Tung Cheng of Cheng Design in Berkeley, CA has a background in building. Jeff Girard, of Formworks in Raleigh, North Carolina, is an engineer by training.

This diversity among the applicator and product producer communities is sure to spawn an even greater number of innovative decorative concrete applications, to which we can all look forward to.