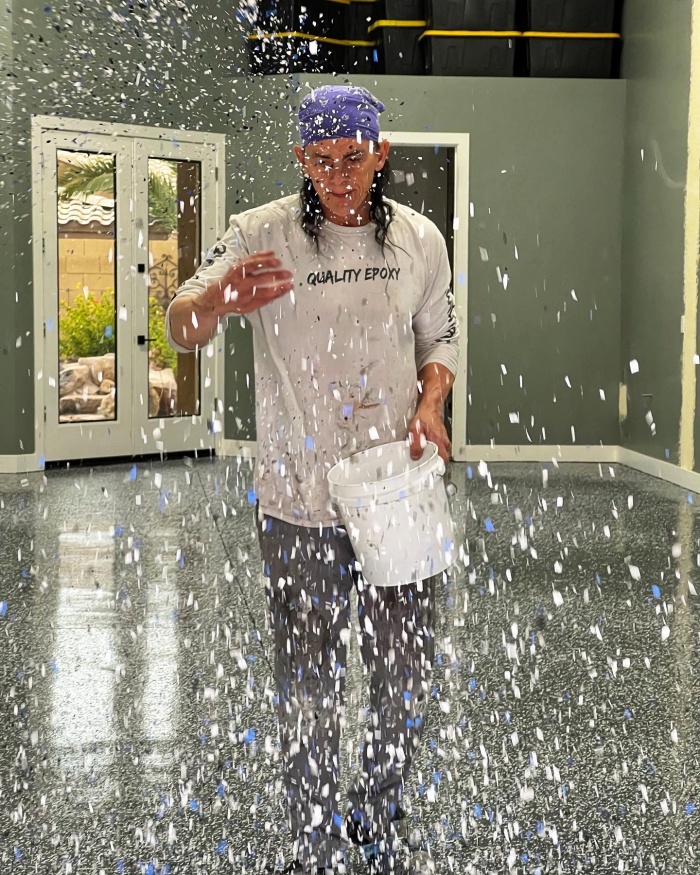

I’ve been wanting to write about the choice of using metallic epoxy or polyaspartic for garage floors for some time. Over the last several years, I decided to stop installing chip floors because I was getting burned out. I really wanted to focus on artistic and dramatic metallic epoxy coatings.

I’ve been wanting to write about the choice of using metallic epoxy or polyaspartic for garage floors for some time. Over the last several years, I decided to stop installing chip floors because I was getting burned out. I really wanted to focus on artistic and dramatic metallic epoxy coatings.

During my time off from installing chip floors, I became a 100% metallic installer only. I look back on this decision and am grateful for it. During that time, it helped me to become an expert in metallics because I only offered metallic.

For many years, I experimented on metallic and even created my own recipe and style. In the beginning of 2021, however, I decided to bring back my chip floors as an option. I did this because I understand that not everyone wants a metallic floor. Likewise, not everyone wants a chip or solid color floor.

Every coating has drawbacks

While focusing my career on metallic epoxy, I discovered drawbacks to every type of coating. The biggest drawback with a metallic epoxy in a garage involves yellowing. Yes, you heard me correctly. Metallic epoxies in garages will begin to yellow. To get the best metallic result, you need film thickness. To achieve the required film thickness, you must use 100% solid epoxy.

On the flip side, you can use 100% polyaspartic but it restricts how thick you can apply it. If you go too thick, your 100% polyaspartic with blister on you. This creates a very restrictive environment to work in. Hence, you must take care how thick you apply it.

Metallic floors are perfect for any indoor installation. Why do I say indoors after all these years of installing in garages? Because in a garage, your metallic floor will turn yellow. Unfortunately, you can’t protect epoxy from ultraviolet radiation. However, both polyaspartic and polyurethane are 100% UVR-protected.

When people hire me to install my 3D-looking metallic floors, I always recommend they allow 48 hours of cure time. After cured, they should immediately apply four layers of wax to protect the floor from scratches. The protection ensures they’ll never get scratches. And a simple buff and rewax will bring the floor back to life.

However, people should never wax a garage floor. Because as soon as anyone drives on it, the hot tires will melt the wax.

Education is key when it comes to metallic epoxy vs. polyaspartic

Being an owner/operator for 20+ years, I’m big on educating my customers and even other floor coating companies on all the ins and outs of our industry’s products. I like helping people better understand products. I also want them to get the best results for their money.

Even though I consider my metallic floors my “babies,” I recommend polyaspartic as the best system for garage floors. Polyaspartic offers 100% UVR protection and it doesn’t scratch like epoxy. Consequently, polyaspartic will always look nice, stay shiny and resist chemicals. Yes, I always come across those who still want metallic in their garage. But I stress they must realize that metallic isn’t UVR-protected. It also scratches very easy because of the high-gloss finish.

I don’t recommend installing metallic to anything outside or exposed to the sun. Instead, use a 100% polyaspartic, taking care not to exceed the recommended mil thickness.

There is also a big misconception that a polyaspartic clear topcoat protects floors from yellowing. This is 100% false. Whereas a urethane topcoat won’t turn yellow, everything under it will. Subsequently, I don’t recommend using polyurethane on top of any metallic floor. It does absolutely nothing.

In conclusion, when it come to metallic epoxy vs. polyaspartic, keep metallics inside. Stick to a polyaspartic coating for garages, patios or anything outside under the sun.