When to Roll Out the Paint. In some cases, paints or epoxy coatings are the right choice for concrete floors.

Although many diehard decorative concrete contractors will argue that you should never paint concrete, there are situations where paint is more than palatable — it’s an appropriate choice.

“When it comes to protecting concrete, epoxy coatings offer several advantages,” says Steve Golich, associate brand manager for Rust-Oleum Epoxy Shield, a coating line developed specifically for garage floors and basements. “Epoxy coatings are both protective and decorative, and because they build a relatively thick film, epoxies hide better than concrete stains.”

Rather than delivering the mottled look of an acid stain, paints are continuous in color, points out Darryl Manuel. Manuel is the president of Vexcon Chemicals Inc. in Philadelphia. “There are times when things almost demand that you paint a floor,” he says, “like when there are different colors within the concrete that you want to hide to make the floor look uniform. And there are times when you want to keep a project’s cost lower than [applying] a full stain and hardener. Concrete coatings provide resistance in one step.”

But not necessarily in one coat, Manuel says, adding that he always recommends two. Others contend that their products do well with a single application.

What’s on the shelf

Concrete coatings for patios and garage, basement and porch floors are available as one-part epoxies, two-part epoxies, acrylic paint and latex-based paint. Developed specifically for concrete floors, some manufacturers engineer their products to resist everything ranging from household chemicals and foot traffic to hot tires and salt. Others are not quite as durable but resist scuffing, fading, cracking or peeling.

You can also make these coatings meet ADA-slip resistance requirements. You do this by mixing in anti-skid additives such as aluminum oxide, Golich says.

Regardless of the type you pick, “It’s important that you use paint compatible with concrete because of its high pH level,” explains Michele Neary, director of public relations for Scranton, Pa.-based United Gilsonite Laboratories. “A normal house paint may not adhere to concrete because of an incompatibility with the concrete itself. The difference in pH may cause the paint to peel up in sheets.”

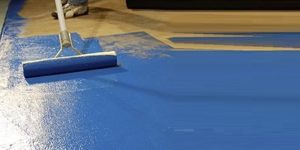

Two-part epoxies, which were developed specifically for more demanding environments like basements and garages, aren’t difficult to apply, Golich says, “Cut in any edges and then roll in 4-foot-by-4-foot sections to maintain a wet edge so that you don’t get roller marks.”

Two-part epoxies can produce a tougher film, but they harden quickly. “Once you mix this coating, you have to use it,” Neary says. If it chips after it’s down, she continues, it’s hard to touch up. “You have to mix up a whole other batch and repaint.”

With her company’s latex-based product, that’s not the case, she adds. “It’s like regular paint. You can open and close it up after you use it.” And it cleans up with water, which makes it all the more attractive.

Many of today’s epoxy coatings are also water-based. The oil-based varieties are geared more for commercial use.

Prep before you paint

Whether a floor is new or old, coated or uncoated, preparation should be a priority.

“To achieve the best adhesion, always remove any coating and contaminants from the surface,” advises Steve Revnew. Revnew is the director of marketing for The Sherwin-Williams Co. “The No. 1 reason for coating failure on concrete floors is poor surface preparation. Be sure to follow the manufacturer’s guidelines.”

Jeff Spillane, senior marketing manager for Benjamin Moore Paints, says if the floor is currently coated and the coating is sound and in good condition, it isn’t always necessary to remove it. Sometimes, the only requirement is a good cleaning and deglossing.

There are many cleaners on the market that work well in this department, including the standard tri-sodium phosphate. For some basements, Golich says, vacuuming the entire surface, using a wet mop to pick up dust and treating dirty spots is all that’s necessary before coating.

Most opaque coating manufacturers recommend a little more prep for garages. After cleaning with a general purpose cleaner and treating oil and grease spots with a degreaser, they say you should evenly apply muriatic acid or an etch powder or concentrate mixed with water over the entire surface. This is particularly important if the concrete is highly troweled and smooth, Neary says.

“Then scrub it with a stiff bristle brush in small 4-by-4-foot sections to work the etch into the concrete,” Golich says. “This opens up the pores and allows for better adhesion.”

“After you etch the surface, it should look and feel like fine sandpaper so the paint can bite into the surface,” Neary says.

If you are repainting a floor, you’ll also need to remove all the flaking paint with a wire brush.

“When it comes to coating a floor, there are no short cuts,” Spillane emphasizes. “Like coatings, there is a wide variety of surface preparation techniques. Determine the preparation needed by assessing the current conditions of the floor and the system you are installing. A rule of thumb is that the heavier the mil thickness of the system, the deeper the profile needed.”

In some cases, an acid etch is adequate for bare concrete. However, if the concrete has a sealer on it or a failing coating, acid can’t be used to remove it. Instead, it must be removed with a shot blast machine. “For smaller jobs, you can rent equipment to do this as well,” Spillane says. “A machine called the Prep 16 by Onfloor, available through independent paint retailers, uses diamond plates to remove the old coating and create a profile.”

After thoroughly rinsing with water, you are ready to coat the surface.

Many concrete paints are self-priming, but some require a primer. You may want to consider first applying a clear protector, Neary says. Examples of this are UGL’s Drylok Masonry Treatment, which is a clear moisture-vapor barrier.

|

|

Moisture can be a monster

“People need to be aware that there are floors that would be better not coated,” Spillane says. “Poor or weak concrete or moisture are the enemy of floor coatings.” A clear sealer will help with adhesion but it will not completely cure the problem, he maintains.

Revnew shares this philosophy. “If you coat concrete with high moisture content , premature failure will occur due to trapping moisture behind the coating.”

While there are more sophisticated tests that you can use, Spillane says, here’s a simple test to determine if there’s excess moisture present. “Either duct-tape down an 18-inch-by-18-inch piece of plastic or lay down a rubber mat and leave it for 24 hours. If, once removed, the floor is wet and there’s water on the back of the plastic, there’s a good chance a coating system will fail.”

In these cases, contractors should opt for a stain, Spillane adds. “Concrete stains generally penetrate and produce a thinner film, which allows them to tolerate less-than-perfect conditions.”

Vexcon’s Manuel says that there’s no need to test for moisture before applying any of his company’s products, as they all are breathable. “There’s no way to control moisture unless you allow it to come through,” he says. He also adds that Vexcon is one of the largest producers of coatings that professionals use to control moisture.

The wait

How long should you wait before coating concrete? Revnew, Spillane and Golich say they always recommend 30 days. “But in today’s market, there are coatings that you can apply sooner than that,” Revnew adds.

Vexcon’s products are one such animal. You can apply these coatings as soon as you can walk on the concrete, Manuel says. In fact, he adds, he has coatings that he uses to help cure fresh concrete as well as coat it.