Laszlo Keszthelyi, owner of Monster Coatings, a flooring company that services the greater New York City metro area, specializes in seamless flooring. He’s been in business for 37 years, beginning with flooring and reflooring elevators in his early years.

“There was always an issue with elevator floors,” he says. Usually clad with melamine and tile, substrates would consistently deteriorate because moisture would travel through gaps in the joints. On average, he’d have to redo elevator flooring every three to six months.

Somewhere along the way, he discovered seamless epoxy floors, which lasted longer because of their durability and waterproofing characteristics. One job soon led to another. Consequently, Keszthelyi began installing floors for metro NYC area transit systems and commercial venues such as restaurants, bars and kitchens.

“In New York, everything goes up not out,” because of space constraints, he says. So, with much of his business involving high-rises, he began to specialize in bathtub-type waterproof seamless flooring designs. They would protect spaces below during normal operations where water was an essential part of the business, like washing.

These floors last between 10 and 20 years, Keszthelyi says. Unlike traditional elevator flooring systems, these systems typically last their entire life cycle between modernizations “We install quite a bit over plywood substrates but mostly over concrete substrates.”

The chemistry behind the product

Some 15 years ago, Keszthelyi started using urethane-modified concrete (UMC) rather than epoxy. About nine years ago, he discovered Kraftig UMC (formerly Perdure UMC), a seamless self-leveling UMC product made by Duraamen. Engineered for floors exposed to chemicals, wet conditions and high-temperature cleaning, the coating withstands everything from spillage to rigid maintenance.

“It’s ideal for applications such as food establishments and breweries washed down daily, sometimes multiple times a day,” Keszthelyi says. “The urethane gives it the ability to withstand hot and cold temperature fluctuations. And the cementitious portion provides the mass to withstand expansion from thermal shock.”

Victor Pachade, general manager of Duraamen, explains his company’s urethane concrete, also known as urethane cement, is a three-component system. It consists of Part 1, a polyol; Part II, an isocyanate; and Part III, a blend of cement, lime and graded aggregates.

“When you mix Part I and Part II together, the chemical reaction releases water and carbon dioxide. The water reacts with the cement and the carbon dioxide reacts with the lime in Part III,” Pachade says. “This creates an impermeable matrix once the urethane concrete cures completely. And this gives the product the property of thermal-shock resistance and moisture-vapor resistance.”

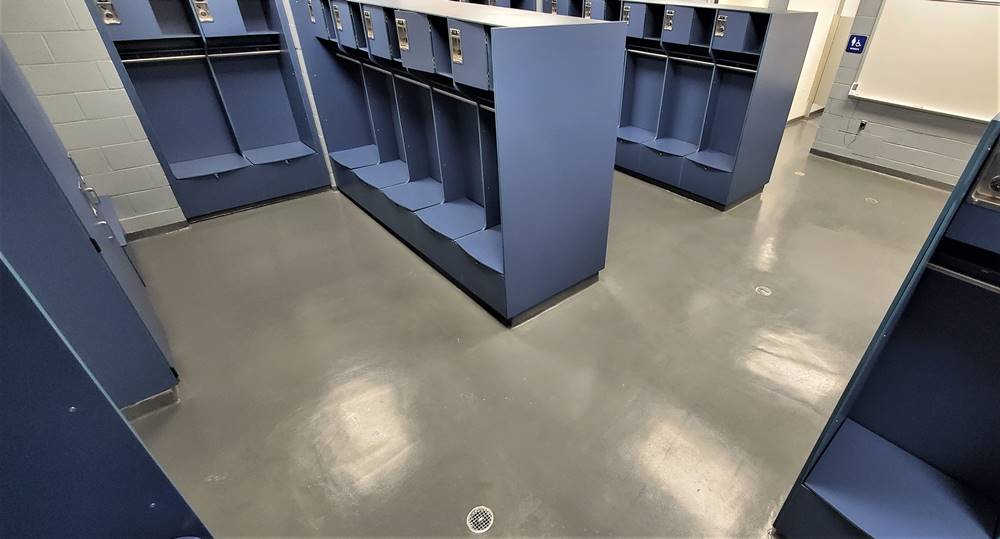

You can apply a UMC like Perdure to a range of substrates such as integral cove bases, slopes toward drains and other inclined surfaces. Manufacturers say UMCs are one of the best flooring solutions for commercial kitchens, such as this one pictured of Pat’s Market, a butcher shop and deli in Lincroft, New Jersey. Floor installed by Form Designs. Photo courtesy of Duraamen

Self-leveling product shaves off time

Kraftig UMC’s other selling points include its resistance to bacteria, low odor and zero VOCs. Its makeup is also non-tainting, meaning it can be installed in food establishments without risk of contamination. For safety precautions, anti-slip traction additives can make it ideal for wet areas.

Not only is the product extremely durable, but “Kraftig UMC is self-priming 90% of the time,” Keszthelyi says. This enables it to even out the highs and lows. “You just clean, prep and apply. In most cases, it accomplishes everything in one step versus multiple steps. This saves time, labor and quite often money, too.”

On fast-track jobs, Keszthelyi adds, Kraftig UMC can easily shave a day or two off the install.

UMC product’s versatility improved

From a workability standpoint, Duraamen has greatly improved Kraftig UMC’s formula over the years, Keszthelyi says. “I’ve used some others that are hard to work with or are too thick.” Although the coating can go on as thin as 1/16 inch, he typically applies it between 1/8 and 1/4 inch. “The finished system could be thicker depending on whether we broadcast quartz or vinyl flakes into it.”

Probably one of the best characteristics of the product, Keszthelyi says, is its base chemistry. “You just change the aggregate and the amount if you go from self-leveling to a cove-base mix,” he says. “You’re not stuck with expensive material that you can’t use in other application steps.”

Kraftig UMC is available from Duraamen in a self-leveling (SL) formulation ideal for floors. It also comes in a trowel-grade (TG) formula designed for sloped or vertical applications.

“The performance of this product is nothing but good,” Keszthelyi says. “I don’t recall any failures. It bonds well to wood, concrete and uneven surfaces that have to be self-leveled or fixed first. It typically combines two, sometimes three steps into one.”

Looking for polyaspartics?

Offered by Concrete Decor Store Perdure P72 - Polyaspartic Polyurea Topcoat

Perdure P72 - Polyaspartic Polyurea Topcoat

by Duraamen Engineered Products Kraftig Urethane Modified Concrete Floor Kit

Kraftig Urethane Modified Concrete Floor Kit

by Duraamen Engineered Products