Photo courtesy of Amazing Garage Floors

Today, consumers have options galore when it comes to transforming plain-gray concrete slabs into colorful floors. Choices include broadcasting chips onto an epoxy basecoat. They also include spraying the epoxy with a specially blended material to achieve a terrazzo-like appearance.

Typically achieved with vinyl flakes, multicolored floors are gaining a foothold nationwide. Besides conventional vinyl chips, a product called Plextone can deliver a similar look quicker and with less product.

The ease of using Liquid Chips

Seagrave Coatings in Kenilworth, New Jersey, makes Plextone, a paint-like material applied over epoxy that resembles a vinyl flake coating. “The biggest advantages to contractors are primarily speed and a thinner topcoat,” says Peter Tepperman, president and CEO. “Our multicolored chips also last longer because they don’t protrude from the surface and require scraping. Plextone Liquid Chips lay flat.”

Because the Liquid Chips lay flat, they require a thinner topcoat for the finishing coat. “It takes 30-40 mil to cover vinyl but in most instances you’ll only need 10 mils with our Plextone,” he says.

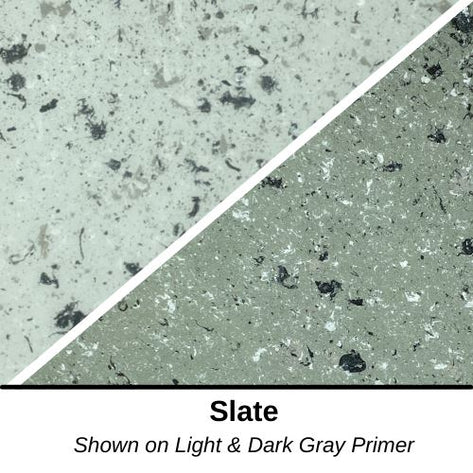

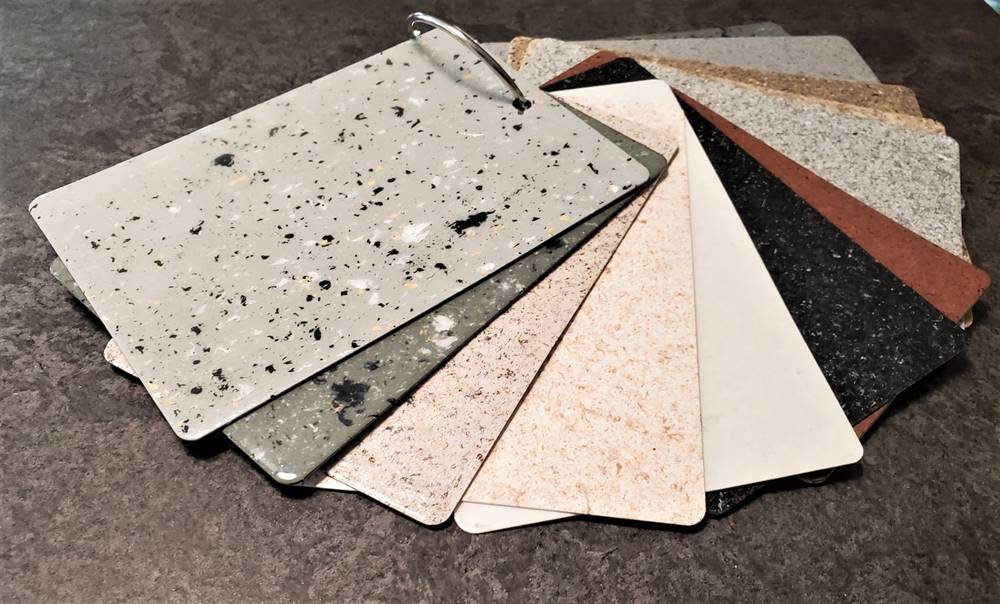

The company’s irregularly shaped Liquid Chips can be anywhere from 1/16 upwards to 1/4 inch in size. Seagrave offers a palette of 16 colors with custom colors available on request. He says most people choose a blend of three or four colors applied over a different colored epoxy basecoat.

Tepperman recommends using a high-volume, low-pressure spray unit or a small cup gun to apply. “Applying the product is relatively easy,” he says. “It’s like applying paint. You need to spray-apply the Liquid Chips uniformly.”

The reliability of vinyl chips

Primarily found in garages, vinyl chip floors can also be installed in offices, medical clinics, clean rooms and “wherever someone needs an impervious floor,” says Michael Raney, owner of Surface Systems of Texas in Houston. He estimates his company averages about 15 such jobs weekly applying its ColorFlake system to both residential and commercial facilities.

Raney is a big proponent of the blends he gets from Torginol, a flooring materials manufacturer based in Sheboygan, Wisconsin. “Service is their middle name,” he says, adding that the company custom blends all Surface System’s ColorFlake offerings. “They are by far my favorite supplier. They innovate a lot and always add new products. Not just vinyl flake blends but quartz, mica and wood chips.”

Most recently, he adds, Torginol introduced a hybrid blend with three different sized flakes — 1/32, 1/16 and 1/8 inch. “It produced a whole different look,” Raney says.

John Hutchins, president of Amazing Garage Floors headquartered in Olathe, Kansas, says he’s been using Torginol products since he first got into the flooring business in 2007. “I love Torginol’s consistency, which is very important to me,” he says.

Currently, Hutchins trains people how to install vinyl chip floors. “Some people get into trouble bouncing around from product to product,” Hutchins cautions. But with Torginol’s products, he adds, you can confidently get the same results time and time again.

Colors and chip size

Both Raney and Hutchins regularly offer their customers about a dozen or so color choices with chips of varying sizes. Blends containing 1/4-inch flakes rank as the most popular choice, they say. Color blends usually contain anywhere from four to eight colors. Whereas brownish blends were most popular in past years, most of today’s customers prefer the grays.

Raney installs a fair share of dual-tone vinyl flake floors in garages of upper-end homes in his service area. These usually include a border around the perimeter. He says he also uses a different color to differentiate the edge of a “car stop.” This is a raised area 3-6 feet from the garage’s back wall that establishes a safe stopping point for cars.

Installation is similar

Before broadcasting vinyl chips or spraying Plextone, installers must profile the floor by diamond grinding or shotblasting. Next, they should repair any imperfections before applying about 10 mils of an epoxy basecoat.

The epoxy basecoat goes on with a roller. Installers then broadcast by hand somewhere between 8 and 20 mils of vinyl flakes. After letting that cure out for a few hours or overnight, installers return to “blow and scrape” the floor and vacuum up the loose flakes. The Plextone method eliminates this step.

To complete either system, installers squeegee and back-roll about 10 mils of a polyaspartic or polyurethane topcoat. Polyaspartics dry faster. You can walk on those floors in a couple of hours and park on them in as few as 12. Polyurethanes are safe to walk on in 12-24 hours and park in 72. Temperature affects the drying time.

All total, the three coats — basecoat, chips and topcoat — should measure 25-30 mils thick. For the liquid system, the coating totals about 8-10 mils.

Lots to like about chip floors

“We like polyurethane better than polyaspartic,” Raney says, for topcoating the vinyl chip layer. “If you can wait, that’s the way to go. It self-levels and just looks better. It also dries a little slower and you can go back and roll it again. You can’t do that with polyaspartic.”

“What I like about a chip floor is the texture,” Hutchins says. “That and the floor looks cleaner with multiple colors. You don’t see the dirt. I mean, garages get a lot of use. You don’t want to have a floor in there that you have to clean every weekend.”

“A chip floor is the cheapest way to get a great looking floor that stands up to a car, chemicals, whatever,” Raney says. Overall, “For price and durability, you can’t beat an epoxy coating.”

www.torginol.com

www.plextonemulticolor.com

NOTE: Liquid Chips and Plextone are registered trademarks of Seagrave Coatings Corp.