The market for concrete countertops has grown dramatically in recent years, and savvy contractors are broadening their skills to address the growing demand for them. However, many have found these projects to be challenging for two main reasons. First, creating the wood forms needed to produce creative shapes and smooth finishes involves some fairly sophisticated carpentry skills that may be beyond the reach of some contractors. Second, because it’s a time-intensive process, the labor costs are high, as is the cost of base materials like melamine, making it difficult to keep costs down and still make a profit.

|

|

|

Preitech, an Augusta, Ga., manufacturer of high-quality forms for the building industry, now offers a Comprehensive Forming System designed to make concrete countertop production easier and significantly more affordable. Preitech’s system uses high-density expanded polystyrene (EPS) forms, a 7-mil clear base material, and a specially designed polystyrene adhesive to allow contractors to produce countertop forms in a fraction of the time it takes to produce comparable wood forms.

|

|

|

|

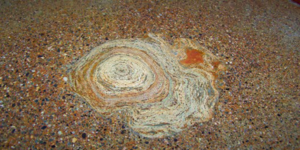

“Making wood forms, especially for highly stylized sinks and countertops, is so labor-intensive,” points out Preitech owner and president Michael Eastergard, “and a lot of contractors have trouble. We’re in the plastics and EPS industry, and we saw the need for developing an alternative to wood forms. Our system has some really attractive features that contribute to a huge reduction in labor costs.”Using Preitech’s system, contractors begin by rolling out the base material on top of whatever smooth surface they’re accustomed to using, such as melamine, lexan, or a steel or aluminum table. Eastergard recommends applying some water mixed with liquid hand soap onto the surface beforehand, using a squeegee to smooth out any bubbles or visible imperfections, which, if not treated, would end up transferring to the concrete finish. A protective coating is then peeled away from the base to expose the smooth, glass-like working surface.

For rails, contractors can select from a variety of Preitech EPS edge forms, which are available in different lengths and thicknesses. Sink molds are available in oval, round, rectangular, half-round and other shapes. Each piece comes with base material preapplied to the edge that comes in contact with the poured concrete.

On site, contractors then apply the tape, taking care to precisely match the edge of the tape strip with the edge of a form piece. The adhesive has been designed to be strong enough to keep it held firmly in place so poured concrete doesn’t leak out.

With wood forms, contractors must drill holes and use screws to securely fasten the forms to the base, a process that uses up a lot of costly melamine because a new piece is required for each form they create. With Preitech’s system, the same piece of melamine can be used again and again, because the base material, EPS and adhesive eliminate the need to drill holes in the melamine and ruin it. The result is a significant savings in material costs.

“Education is one of the most critical things in the quality production of concrete countertops,” says Eastergard. “It’s a relatively simple process, but there are some tricks that must be learned. Once contractors learn how to use this system correctly, they can literally double or even triple their production capacity without having to add another employee.”

Preitech distributes in all 50 states, with major fulfillment centers in Pennsylvania, Washington, Oklahoma and North Carolina. Opportunities for contractors to learn Preitech’s system are being scheduled at major decorative concrete training establishments over the next several months.

www.preitech.com