When blueprinting the process of forming cast-on-site counters, an important detail that’s overlooked, is using the right material for the job.

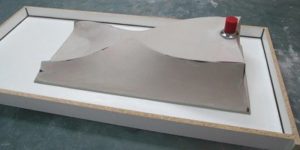

When you’re building a house, the most important part is the foundation, because without a good foundation you have nothing. Well, the most important part of cast-on-site counters is the sub-board.

We at Kipper Crete countertops strive for perfection, and when picking from the many materials that could be used for our sub-board we choose only the finest available. We choose a material that not only will last a lifetime but one that is water-resistant, won’t warp, and is clean and easy to work with. What is it, you ask? There are a few choices, and they are all good products that prevent water loss during the curing stage. These materials are Azek, Comma Board, or XO Board, which are all made by different manufacturers. (Some are only available regionally.) All of them are water-resistant and made of PVC. The Comma Board and XO Board are smooth on both sides. The Azek, which is great because it comes in 16-foot sheets, has small grooves but is still a boon for cast-on-site counters because the grooves allow the concrete to interlock itself with the board.

We at Kipper Crete countertops feel that saving steps (not cutting them) is saving money both now and later. To help preserve the future of the cast-on-site market, you have to be willing to go the extra mile, for you have to see the ending in every beginning.