A random sampling of concrete countertops created across the country display the ingenuity of a cadre of today’s decorative concrete artisans. Read on for an overview of three projects:

One up on granite

Shane Moseley, a concrete artisan by trade, moonlights as a graphic artist in his spare time. So when the owner of Custom Home Updates in Champaign, Illinois, can combine his two skill sets and build artwork with a useful purpose, he considers it a huge plus.

Photos courtesy of Custom Home Updates

Such was the case in this kitchen renovation where the homeowners wanted concrete countertops that looked like black granite.

To set the stage, Moseley used Concrete Countertop Solutions’ Z Counterforms and reusable Rock Face form liners. Constructing cast-in-place countertops and islands with CCS’s forms is a simple process, he says. It involves placing Quikcrete Sand/Topping and Z Liqui-Crete from CCS into forms. These forms are lined with 1/2-inch backer board and plastic-coated fiberglass mesh and rebar.

“People really love (these countertops’) thicker edges and no seams — two things you don’t get with granite or marble,” he says. “You don’t have to oil them as with granite or marble either.”

Going for the vein

Once the tops cured, Moseley removed the forms, sanded the edges to eliminate sharp areas and vacuumed off the dust. He then used Behr water-based premium stains to transform the ordinary-looking gray tops into countertops that looked like black granite.

First, Moseley applied a dark-black stain over the entire surface. He then mixed a dark brown stain with the black and ragged it on “here and there.” This technique, he says, is used to form cloudy areas like you find on some stone.

To create a realistic marbling vein, Moseley used a brighter brown color applied with a large feather. Finally, he sealed the tops with a glossy, food-safe polyurethane.

“I can mimic any marble or granite if I have a photo to use as a sample,” Moseley says.

An interesting feature of these countertops is that the coloring doesn’t have to be permanent, he says. “These can be ground off and re-stained in the future to create a new look or please a new homeowner.”

Made in the USA

A potter who lives in George, Washington, was finally getting her own, long-awaited studio closer to home. A socialite and staunch organizer of local events such as July Fourth and other celebrations, she had a red, white and blue building built in her backyard. She wanted to carry the patriotic color scheme inside with a freshly placed concrete countertop. She envisioned the counter doubling as workspace and a tabletop for community events.

The potter wanted the countertop’s base to be a tan, khaki color with random swaths of red, white and blue. To deliver the goods, she knew just the woman for the job. She chose Christina Arnall, co-owner of D.C. Custom Construction Inc. in Quincy, Washington.

Seams are in

Arnall built the 4-by-14-foot center island off-site in her own studio with Ashby Admix SR countertop mix. For the red, white and blue accents, she used dry pigments from Direct Colors. She mixed various combinations of Titanium White, Charcoal, Fire Rose, Royal Blue and Navy Blue.

Since there were going to be several large, open, unsupported areas, she decided her standard 2-inch-thick countertop would perform best. For the sealer, she chose SureCrete XS-327 in semi-gloss.

She nixed the idea of one long piece. Instead, “We opted to seam (the countertop) in two areas and incorporate them in the design in typical Ashby style.”

Which was a wise decision. The studio’s location would have made it impossible to safely cart the piece in its full length. Not to mention, the combined countertop sections weigh more than 1,400 pounds.

Arnall says the potter was thrilled with how the countertops turned out, which, in turn, made her very happy. “When I first started making concrete art, she was the first person who wasn’t family that I invited into my studio to critique my art,” says Arnall, who specializes in concrete “paintings” and custom shower panels. “She had a huge influence on me.”

Yippee ki-yay

With horseshoes and branding irons — among other touches — Ben Ashby captures the wild West feel with this kitchen redo. It’s in a refurbished house on a working cattle ranch on the Grand Canyon’s north side near the Arizona/Utah border.

The celebrated artisan crafted his signature counters and island with his Ashby Countertop System line of products, starting with Ashby SR Admix and sealing with Ashby Super Seal and CounterSeal 3. He integrally colored the countertops and concrete sink with varying doses of Davis Colors 5237 (San Diego Buff).

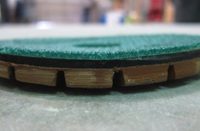

Ashby incorporated three of his edge forms into the design. He used Broken Flagstone on the island. Barbwire surrounds the backsplash made with corrugated metal from the original roof. And along the countertop edges, he used a combination of Random Plank and Weathered Wood. Afterward, he acid stained them.

Branding at its best

The homeowners held off redoing the cabinets until after Ashby installed the concrete so they could match them precisely. That part of the project is yet to come.

To highlight the homestead’s name — the Box Bar Ranch — Ashby created an oversized replica of the brand out of metal. He then mounted it on the front of the island and flanked it with old horseshoes. Although the ranch’s official name is Box Bar — with a box sitting on a bar as its brand — locals call it Top Hat for an obvious reason.

Getting to the ranch was a real trek, Ashby says. He had to get off a main road in Utah and travel 30 miles down a dirt road. “I ruined two tires going to the ranch over the time I worked there,” Ashby says. He also adds there’s no electricity at the ranch. A generator provides the energy needed.