Summertime brings challenges to almost everyone in the concrete industry. Heat and humidity can turn an ordinary job into a frantic scramble of chaos, frazzled nerves and possible mistakes. Knowing what to expect and how to deal with the weather can prevent costly problems, errors, and expensive redos.

Hot summer days severely decrease the working times of setting concrete and increase surface drying. Heat accelerates curing, so early strengths are boosted, but moist curing must be more carefully monitored in the summer to prevent curling and too much drying. And high humidity, cool mornings and hot afternoons make sealing an exercise fraught with anxiety.

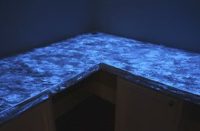

In summer 2011, I spent time in the Cayman Islands working on a variety of projects. The first one was a large outdoor cast-in-place bar top that needed about 2 cubic yards of concrete. I worked with the local batch plant to customize the mix, not only to tailor it for appearance but also to extend the working time.

While a conventional concrete truck mixed and delivered the concrete, it had to be wheelbarrowed to the work site and hand-placed by the bucketful. Summer daytime temperatures routinely hover around 88 F (31 C), and with the lengthy amount of time it takes to dispense, move, place, compact and strike off concrete, I knew that I would need more help to extend the working time.

Heat and working time

Heat accelerates chemical reactions, speeding up the hardening rate and shortening the time we have to work with the concrete. As a general rule of thumb, an increase of 20 F (11 C) reduces the working time by about 50 percent. So when the temperature is 90 F (32 C), setting time is about half as long as when it’s 70 F (21 C).

There are two effective ways to extend the working time of your concrete. One way is to use a set-retarding admixture. I used this approach for the cast-in-place project. Another way is to chill the concrete by using ice as part of the mix water. This is a method I use when casting in my shop. And both methods can be combined to greatly extend the working time, which is what I do when I cast using rapid-hardening cement in my concrete.

Set-retarding admixtures

Type B set-retarding admixtures conforming to ASTM C494 are a safe, effective way to gain more working time, usually adding an hour or two depending on the mix, the retarder and the temperature. The retarder the plant added gave me a full two hours to work with the concrete. I had specified a 4-inch slump, and the concrete maintained this throughout the pour, even up to the last bucketful.

The advantage of a set-retarding admixture is that it can be added to a mix without affecting the mix’s other ingredients. One disadvantage is that the effectiveness of retarders is dependent on temperature, so higher temperatures require higher doses. This can increase the cost of the mix as well as potentially affect early strength gains.

Putting ice in it

As I mentioned, using ice to cool concrete is also an effective method to increase working time, since ice is a potent chiller. The chemical reactions occurring in fresh concrete slow down considerably at cold temperatures. This is why concrete can take much longer to set in the winter. In fact, the set time can be twice as long at 50 F (10 C) as it is at 70 F (21 C) and four times longer than it is at 90 F (32 C).

What makes ice so potent is that it takes a lot of heat energy to melt it. One pound of ice needs 144 BTUs of heat energy to melt. What is left is one pound of cold water at 32 F, freezing temperature. It then takes only 30 BTUs to warm that cold water to 62 F (17 C). Ice is a much more effective chilling agent than cold water, and it is more practical to use ice than to try to refrigerate all of the mix ingredients.

It is only when the concrete starts to warm up that the working time begins to shorten. With a bit of planning, this happens after all placing and finishing is completed.

While admixtures do not affect mix proportions and can even be added at the last minute, using ice requires preparation and forethought. Ice is an integral part of the mix design, accounting for part of the mix water. You MUST NOT simply add some ice to the mix. It is not possible to add ice to an existing batch of concrete without grossly affecting the water-to-cement ratio.

Estimating the right amount of ice to substitute for water and achieve a target mix temperature requires a bit of math, knowledge of the mix design and information about ingredient temperatures. There is no rule of thumb for using ice to cool concrete. The Portland Cement Association’s “Design and Control of Concrete Mixtures” explains the calculations, and my company, The Concrete Countertop Institute, sells an ice calculator with our mix calculators.

The importance of a moist cure

Once the concrete heats back up to the ambient temperature, it begins to gain strength at an accelerated rate. Good curing practices are essential at any time, of course, but especially during summertime.

Concrete needs moisture to cure, and high temperatures increase drying rates, so a moist cure (keeping concrete wet so it can gain strength) is essential. In some areas, summer heat brings high humidity, which is actually good for concrete. In other areas, summer is scorching hot and bone-dry, and keeping the concrete moist while curing is a challenge. This is the case in Phoenix, Ariz., for example. Summer can also bring beating sun and wind. This was the case in Grand Cayman, and my home state of North Carolina is even worse.

Wet-curing concrete is the key to preventing shrinkage cracks, curling, lower-than-expected strengths and a host of other problems. Exterior concrete exposed to the sun and wind should be covered with a curing blanket, wet burlap or a curing compound to help hold in moisture and prevent drying. Interior concrete should also be covered and monitored for moisture. Simply lifting up the covers and spritzing the concrete with water once or twice per day can make the difference between weak, dried-out concrete and strong, properly cured concrete.

Windbreaks should be set up to keep hot, dry air from blowing across the concrete. Wind greatly accelerates evaporation and is a prime cause of plastic shrinkage cracking in freshly poured slabs.

Interior concrete is often sheltered from the wind and sun, but good curing practices are still important with indoor pieces.

Sealing and humidity

When it comes to sealing concrete, temperature and humidity can play a significant role in achieving success or failure. Many concrete sealers (coatings especially) prefer or require dry concrete. Moisture in the concrete can compromise the bond with the concrete or even prevent the sealer from curing properly. Different sealers tolerate moisture differently, so it is important to consult the sealer manufacturer’s instructions.

Balancing sufficient moist curing with adequate drying takes care, practice and experience. Problems commonly arise when the process is rushed. Ideally concrete is wet-cured for as long as possible and allowed to dry only once the concrete reaches adequate strength. Drying would then occur slowly and evenly, permitting the slab to lose moisture without curling, shrinkage or cracking. Only after the concrete’s moisture levels reached acceptable levels of dryness would you seal.

It is a common notion that concrete “breathes.” What this means is that as cool concrete warms up, the air and water vapor in the concrete expands, leading to the concrete “exhaling.” Likewise, air and water vapor contract as the concrete cools and “inhales.” Sealers applied to cool concrete can bubble or blister when the concrete warms up before the sealer fully cures. The best time to apply a sealer is when the concrete will remain at a stable temperature for a long time or when it is beginning to cool down.

Even after proper curing and drying, hot temperatures and high humidity levels are factors to consider during the process of sealing. Just like concrete, two-part (catalyzed) finishes react faster in warmer temperatures, drastically reducing the sealer’s pot life. Applying sealer to hot concrete doesn’t just lead to bubbling or blistering due to “breathing” — it can also result in uneven finishes. Heat causes the liquid carrier (solvent or water) to evaporate faster than the fresh sealer can flow out into a smooth film.

For the Cayman Island bar top, I used a two-part sealer (StoneLok 2K, from Richard James Specialty Chemicals Corp.) that has a fairly short pot life at elevated temperatures. To ensure the sealer remained workable and that the finish looked good when I was done, I chilled the components in a refrigerator overnight. While on-site, I stored the cooled sealer in an insulated cooler so that even after mixing, the sealer’s pot life was extended. This gave me time to apply the sealer carefully without rushing and without worrying about the sealer getting thick. It is very important that the sealer have the same consistency at the beginning and at the end of the sealing process. Otherwise, the texture and sheen won’t be the same.

Summertime heat is a fact of life many of us have to face. Knowing how to deal with its effects can make our jobs easier and more relaxed — and it can also increase quality and save money.