There are some important, key factors that can help you be more successful with your concrete countertops. Here I will discuss a fundamental ingredient: water. We’ve all worked with concrete and water, but working with a material isn’t the same as knowing how it works.

Before getting into the nitty-gritty of making “good” concrete, let’s step back and consider the final product we’re making. If we’re making a concrete countertop, then the two broad characteristics we are most interested in are looks and strength. Looks are important because we don’t get paid for concrete that doesn’t look like what the client wants. Strength is important because cracked concrete is seen as a failure and a problem.

The importance of water

Many of the characteristics of concrete that are important to our clients and us are dictated and directly affected by water. The proportion by weight of water used relative to the weight of cement in the concrete is called the water-to-cement (w/c) ratio. Factors like early and ultimate strength, color, set time, porosity, durability, shrinkage and curling tendency are all controlled by the w/c ratio. Too much water makes for weak, pale, crack-prone concrete.

As we all know, concrete gets stronger when less water is used, yet many times excess water is added to the concrete (for example, to improve workability) with no regard for the consequences. Think of the new concrete as trying to grow crystals. If there’s too much water keeping the crystals apart, they can’t knit together, and therefore the whole structure is weak and porous.

Knowing that water plays a critical role is the first step. Starting with a low w/c ratio is important, but maintaining that ratio is also just as important. Good quality concrete countertop mixes often use w/c ratios ranging from 0.30 to as high as 0.38. It does no good to arbitrarily add more water simply to improve workability. Not only does the amount of water increase, the exact quantity you’ve added is unknown.

Water and color

Water plays a big role in the appearance of the concrete. The more water that’s added, the paler and more washed-out the color will be. Think of grape Kool-Aid. If you add more water, it gets paler. Aesthetics are critical, and if two batches of concrete look different your clients won’t be happy and even may refuse to pay. That’s why it is so important to measure your water carefully, by weight, and record the amount of water used in your color formulas.

Use superplasticizers, not water, to add workability. Superplasticizers can turn concrete that looks dry and crumbly into something smooth, creamy and pourable. The concrete will be better-consolidated, and the resulting casting will be crisp, precise and have significantly fewer pinholes or voids.

Water’s role continues with curing

Water still plays a critical role even after casting. Over time, the water and the cement react. This is called hydration, and it continues for as long as there are water and unreacted cement particles present. We all know concrete takes time to gain strength. The longer concrete’s internal moisture levels are high enough, the stronger it will become.

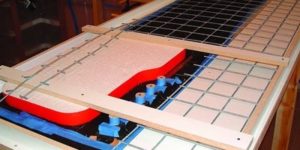

Curing is very important early on when the concrete is young, weak and prone to losing the internal moisture it needs to get strong. Typically concrete countertops are wet-cured under plastic while still in the molds for one to four days. Afterwards, wet processing to grind, hone or polish the concrete maintains the moisture levels and prolongs wet curing. Only after five to seven days do most concrete countertops begin the drying process so that they can be sealed.

Good curing means covering the concrete with plastic and trapping evaporated moisture. All of the water the concrete will ever need to fully hydrate is added to the concrete during mixing. When the concrete is wetted down with water during curing, we’re not putting more water into the concrete. The added water simply acts as a buffer, preventing evaporation from drawing moisture out from inside the concrete.

As concrete cures, it gains strength and gets less porous. Denser, more mature concrete retains its internal moisture better than new, porous concrete. That’s because the internal crystalline structure that’s growing and developing is denser in older concrete and looser and more open in newly cast concrete.

When concrete dries out, hydration eventually stops. Adding water will restart hydration for the areas that have access to that added water. Letting your concrete dry out is an eventual necessity for sealing, but premature or uneven drying can cause problems that include color variations, cracks, curling, low strength and porosity.

While plastic sheeting is a simple way to keep concrete moist, other means are used too.

Water and GFRC

Glass-fiber reinforced concrete (GFRC) uses specialized acrylic polymers to aid in retaining moisture. The polymer slows evaporation by reducing porosity, effectively acting as an internal curing membrane. Typical curing methods still help, but because the concrete loses moisture more slowly, GFRC is typically covered with plastic only for the first day.

Conventional concrete mixes that don’t use polymer must rely on external curing methods to maintain high internal moisture levels, so good curing practices become very important.

Regardless of the type of concrete, the longer it wet-cures the stronger and better it will be.