A waterproof residential balcony is a common amenity for custom homes, condominiums, and resort properties. Solid surface balconies are easy to maintain. They also ensure proper stormwater drainage away from the building while protecting outdoor patios below deck.

New home designs, including building renovation projects, may include a waterproof balcony. This is especially true if the building faces natural features such as a mountain range, a lake, river, or a coastline. It’s only natural to note that these surfaces catch the brunt of wind-driven rain and snow, and exposure to high humidity in many parts of the country. That said, the balcony remains one of the ultimate gathering places for

outdoor entertainment or that early morning coffee at sunrise.

Moisture Damage Hiding In Wait

Perched along Florida’s Atlantic coast is a residence that has seen its share of weather events and exposure to the elements. What was unexpected was a serious moisture-related problem hiding below the surface of the 5/4 decking laying atop rolled asphalt roofing. Water leakage appeared through the ceiling below.

After removing the wood decking, they discovered the problem when stepping on the balcony and it felt spongy. It wasn’t until the homeowner stepped onto one of those soft spots that his foot went through the deck, and he found himself standing between rafters on the ceiling of the patio below. In this way, dry rot was discovered.

|

|

Dry rot is commonly the result of improper ventilation or of moisture intrusion caused by poor construction methods, inferior building materials or deterioration of an existing building finish. Dry rot can lead to a host of health-related problems as well as the loss of a building’s structural integrity.

Fixing the Dry Rot Problem

In the case of this single-family residence, it was determined that the entire residential balcony subfloor would need to be replaced, including several of the supporting 2”10” floor joists.

Ralph Schoenherr, a retired public infrastructure professional with an affinity to restoring classic cars, gave special attention to this project, in part because it was his daughter’s home.

Determined to find a better building material, Ralph’s online search led to a building material known as Cem-Rock eXtrme Subfloor ¾”. The material is new to the US market, and more commonly referred to as MgO board, for magnesium oxide board. Unique to this material is its hydrophobic characteristics, which got immediate attention. The fact that Cem-Rock is also fireproof made it even more appealing.

As Ralph explains, over time moisture will find its way in, and it’s hard to identify a problem until it’s too late, especially with minimal slope. Even treated wood products, once you saw cut and perforated the material with fasteners like nails, screws or staples, this creates endless opportunities for moisture intrusion. CemRock eXtreme Floor ¾” MgO, on the other hand, will never deteriorate in the presence of moisture.

The plan for success

From the outset, Ralph had an interest in using a cementitious waterproofing system for the residential balcony. That search led to the ConcreteDecorStore.com, where he found products by Stone Edge Surfaces, and additionally, he found the Cem-Rock eXtreme Subfloor product.

As Ralph explains, a phone conversation with the store’s owner, Bent Mikkelsen, involved a lengthy discussion about the benefits of using Cem-Rock in place of a plywood material. Among the aforementioned benefits of Cem-Rock, there would be no required need for a vapor barrier and diamond lathe when using plywood. Not using diamond lathe eliminated the need for staples to hold the lathe in place. In fact, code requires you to install staples two inches apart. That’s a lot of staples! Ralph states that the beauty of using Cem-Rock and Stone Edge products is that it allows for scheduling flexibility of the project stages.

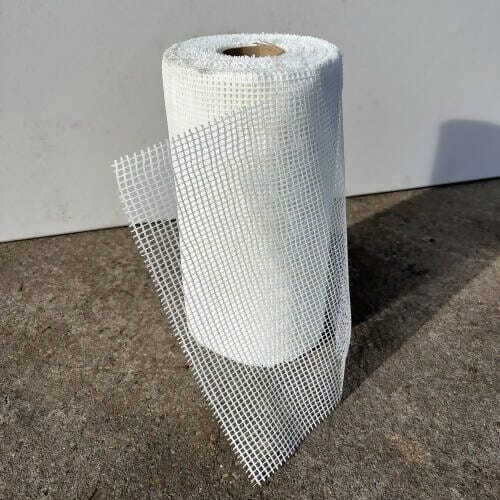

Instead, they roller-applied Stone Edge Deck Resin to the surface of the Cem-Rock and fiberglass mesh embedded into the wet surface. They then applied a second, wet-on-wet coat of resin and followed with the broadcast of a 30-mesh silica sand to refusal. The use of silica sand creates a coarse sandpaper type of surface that gives a topical coating something to hold onto.

The process continues

The next day, they removed the excess sand with a leaf blower before applying a 1/8″ coat of the Stone Edge Pro Bond Ultra. It rained that night, but had no effect on the curing of the Pro Bond Ultra. A gentle breeze the following morning dried the deck quickly so they could apply a bond coat of Stone Edge Primer 100.

The deck was now ready for a 3/8″ layer of the Pro Stamp Mix. Christi Tamayo of Select Surfaces Solutions in Orlando provided support with the use of their texturing skins, used to create a natural stone finish before the Pro Stamp Mix hardened.

The Finishing Touch

With the balcony project nearly complete, the final step was the application of a water-based concrete sealer. Because the homeowner wanted the balcony color to closely match the color of their wood boat dock, they mixed Stone Edge Surfaces liquid color pigment (bronze) with Pro Seal and roller-applied. Two color-coats of Pro Seal, in addition to a coat of Pro Seal without color added, produced a natural matte

finish. The balcony renovation was now complete.

As Ralph explains, once they installed the Cem-Rock eXtreme Floor, the deck felt like you were stepping onto a concrete surface. With the cementitious waterproofing system applied to the surface, it gave the residential balcony a really solid feel while adding aesthetically to the home.

“We feel we have eliminated the potential for moisture problems in the future, and my daughter’s family can now enjoy their balcony for years to come.”

Coming Soon: How Cem-Rock eXtreme ¾” MgO board is used on multi-family construction projects to minimize insurance claims associated with faulty washing machines and dishwashers. Cem-Rock eXtreme ¾” (MgO) boards include an added level of fire protection and sound proofing to multi-family residences.

Products mentioned in this article

Offered by Concrete Decor Store Cem-Rock Extreme Floor - 4' x 8' - 3/4" Thick

Cem-Rock Extreme Floor - 4' x 8' - 3/4" Thick

by Cem-Rock Pro Stamp Mix - 50 lb bag

Pro Stamp Mix - 50 lb bag

by Stone Edge Surfaces Lightweight Mesh Rolls - 4.4oz Mesh

Lightweight Mesh Rolls - 4.4oz Mesh

by Spiderlath