As part of a public kindergarten renovation project in Villemomble, France, the town approached Eqiom Bétons to present samples of finishing possibilities for the Joseph Gallieni School’s outside pathways. And, in the end, the project turned out just ducky with the help of red glass aggregate.

From the many possibilities presented — based on an extensive collection from the company’s Atelier showroom in Montreuil — samples were made. The winning sample involved Articimo Stabilized. This is a totally white mix made from white cement and white aggregate from the Eqiom Saint-Soupplets concrete plant.

Articimo is Eqiom Bétons’s product line dedicated to floors, with other mixes formulated for techniques such as polishing and stamping. The Stabilized mix is designed to reveal the sand of the concrete rather than bigger aggregates.

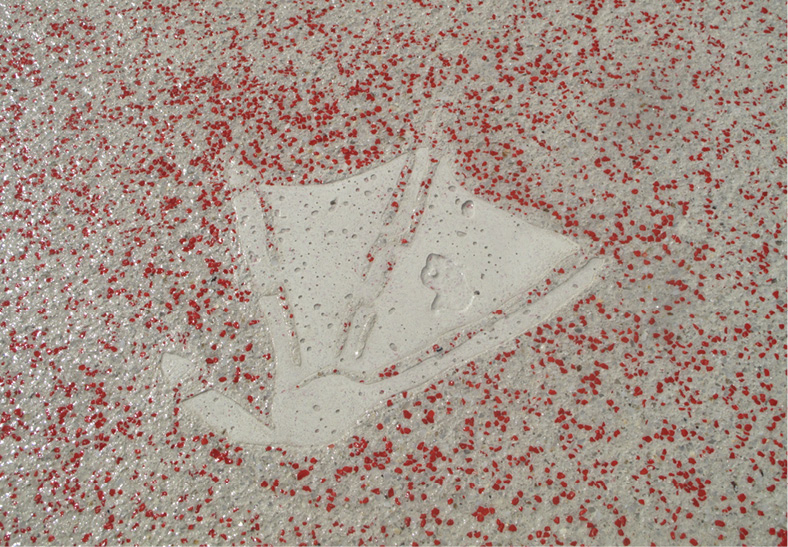

To make the white concrete surface even more appealing, Eqiom spiked it with red glass aggregate and incorporated custom-made stencils to form a series of animal tracks on the pathways. Besides being a cute addition for the children to enjoy, the paw prints also serve as wayfinders on the path.

“This original idea allows the children to make fun trips,” says Christophe Vaissier, special concrete and decorative concrete manager of Eqiom Bétons. He is the one who is responsible for the Paris and Normandy region. He also organized the initial meeting. For example, wolf tracks lead to the area where children nap while duck feet imprints lead to the cafeteria.

Mineral Floor, a partner of Eqiom Bétons and a member of its Créateurs de Sols Béton (Creator of Solids Concrete Network), was selected to do the job. The job combined several techniques, including placing the concrete with a pump.

The nitty-gritty

Mineral Floor applied the custom-made opaque stencils and broadcast the 2-4 mm red glass aggregate instead of throwing down color hardener. The glass, made especially for concrete, was supplied by a German manufacturer. The crew applied the glass in a proportion of 1 kg per square meter. The surface was then sprayed with Artistab deactivator. This proved to be a bit challenging, Vaissier says, because the space was very small.

Mineral Floor applied the custom-made opaque stencils and broadcast the 2-4 mm red glass aggregate instead of throwing down color hardener. The glass, made especially for concrete, was supplied by a German manufacturer. The crew applied the glass in a proportion of 1 kg per square meter. The surface was then sprayed with Artistab deactivator. This proved to be a bit challenging, Vaissier says, because the space was very small.

“Artistab is a specific deactivator for concrete surfaces, dedicated to our Articimo Stabilized solution,” says Vaissier. “It is a very thin retarder compared to the traditional products on the market. It must be eliminated with a high-pressure jet between six and 24 hours after the end of the concrete pouring (depending on the climate).”

The following morning, the concrete was washed, speckling the surrounding soil with red and revealing the animal’s paw paths. Once dry, the Articimo Stabilized was sealed with Ideal Work’s Ideal Sealer Regular, a protective resin.