As we transition from fall to winter, the days get shorter, the leaves fall into the concrete we are trying to finish, and the temperatures start dropping. The concrete blankets come out and cold-weather concrete practices start to take place. The changes in how concrete is placed should also trigger changes in how sealers are applied.

Concrete Sealers

Sealers are applied to concrete surfaces to protect them from the elements and extend their useful lifespans. There are two main types of sealers: film-forming varieties that enhance the surface with color and sheen, and penetrating sealers that go into the concrete’s pores and seemingly disappear.

Choosing the Right Concrete Floor Sealer

Penetrating or film-forming, water-based or solvent-based, your sealer is just as important as any other element of your project. Here’s a guide for sorting through your options — plus tips on some clever effects you can create with them.

Hot-Temperature Effects on Sealing Concrete

Heat is the universal catalyst. Apply heat and things tend to happen faster. Consider what happened the last time you accidentally grabbed a hot plate. I am sure your speed increased dramatically as you looked for a place to put the plate down. The same thing happens with sealers at the molecular level when the temperatures go up.

Don’t Get Burned: Safety While Using UV-Cured Concrete Coatings

First and foremost, using ultraviolet curing equipment for concrete coatings requires diligent safety practices. Compare it to "a welder’s flash on steroids." Sunglasses and long-sleeved shirts are not enough. UV emitted by curing equipment can be many times brighter than the sun.

When Sealers on Polished Concrete Cause Problems

Is the solution to polished concrete maintenance educating the customer on proper procedures, or is it developing better sealers to provide the customer?

Maintaining Sealed Stamped Concrete

What do you think of when you hear the term "sealer maintenance"? If you are like most in the industry, the first thing that comes to mind is waxing or buffing a previously sealed interior floor. Well, with spring upon us, it’s a great time to talk about another kind of sealer maintenance – maintaining exterior stamped or textured concrete.

Pouring a Concrete Countertop in Place at a College Bar

The owner, an old concrete contractor, wanted to replace the two bars with concrete. The goal was to add ambience and character to the bar with a material that could be hosed down along with the floors. The owner also wanted seamless tops, making this a good candidate for pouring in place.

Concrete Artisan Develops New Product While Business is Slow

Artisan in Concrete – Change is what they do. Quick and Ickes started in business together in 1998 as a commercial pressure washing company.

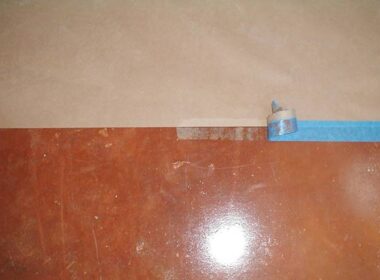

Most Common Problems with Tape on Concrete and Their Solutuions

It is widely known that the decorative concrete industry has struggled with tape issues for decades. These range from the tape tearing when overlays are being applied, or stain bleeding under the tape, to adhesive effectiveness when the tape gets wet.

Why Penetrating Sealers Are Sometimes Your Best Choice

One of the most common questions I get asked is, “What is the best sealer?” My answer to this is, “It depends.” While this may seem like I’m dodging the question, it really gets to the heart of the issue. Selecting a finish solely based on how good it is said to be can often lead to undesirable results.