For many of you, the journey to Las Vegas for the annual WOC show is not an easy one. Weather around the country never fails to be an issue. Getting the Concrete Decor RoadShow trailer and materials for our Decorative Concrete LIVE! sponsors to Vegas was another one for the history books.

Co-piloting the drive to WOC this year was one of Concrete Decor’s most regarded sales executives, Troy Ahmann. Troy has recently rejoined us at Concrete Decor, after a few year hiatus. We are grateful to have him back in the fold. Along with us was Mikkelsen family member, Marc Vollesen. Marc is a journeyman concrete finisher from Denmark, looking for new opportunities to take home and implement.

Departing Eugene, Oregon, the morning of Monday, January 15, was more like stepping onto an ice-skating rink in tennis shoes. The first few hours of our drive put us a whopping 20 miles down the highway. For anyone who deals with snow covered roads each year, you know how important it is to keep your foot off the brake pedal. This is especially true when you’ve got 20,000 lbs of equipment, materials and supplies in tow.

I drive the RoadShow trailer to WOC each year because, if for some reason the trailer doesn’t show up in one piece, Decorative Concrete LIVE! would not happen and I wouldn’t want to put that blame on anybody else. Considering the many months that go into getting ready for this event, a safe and timely arrival is really important.

A Vegas welcome

Despite catching a cold because of the chilly winter temps in Oregon, we showed up at the Las Vegas Convention Center parking lot at 7:00 a.m. sharp on Wednesday morning. We were greeted by a gorgeous sunrise and truly the best winter weather Las Vegas had to offer. What a relief!

Leading the charge for Decorative Concrete LIVE! every year is Emil Gera of Gera Concrete in Pennsylvania. Emil was accompanied by Rebecca and Gaetano Fuscardo, Matt Sampson, brothers David and Joshua Rebello, Terence Meehan, Josh Russell, and welcomed newcomers, Josh Mussman and Sat Jassal. They all flew into town ahead of time to get to work. Their early arrival is almost always met with jet lag due to cancellations, delays, etc. But that never seems to break their spirit.

This crew of concrete craftsmen has a work ethic that is unbreakable. They are true warriors of the concrete trade. Rebecca Fuscardo is cut from the same cloth and her get-it-done attitude makes every one of us want to work harder.

Dustin Thornley with American Specialty Glass and the crew from FirmeCrete that included Ray Cano, Michael Hernandez, Julio Ceja and Cory Hanneman made lighter work for everyone with their support. Also involved was Jeff Kudrick, who brought new outdoor living products into the space to help with theming.

A passion for decorative concrete

Decorative Concrete LIVE! is a passion for everyone involved, including myself. All told, there are 30+ artisans involved with Decorative Concrete LIVE each year. We eat up space at local hotels while another dozen of us stay at a VRBO nearby. The time together is fun, despite the need to have ourselves fed and ready to go by 6:15 each morning.

Most nights my sleep was interrupted hunting for another bottle of water in the kitchen. It was a memorable moment each night. The grunts, coughs, hacking, snoring or nose blowing, made me realize just how thankful I am to have such great people in my life. People who do what they love, in spite of everything this trade throws at them.

Like most years, rain happens at some point in time during preparations. And without fail, the rain came just when we thought this might be a year without rain. Shame on me!

It rained part of Saturday, all day Sunday and Monday with an added measure of the wet stuff the opening morning of the show. By this time, we were no longer in charge of anything, we were simply doing our best to finish what we started. That happened on Thursday as the show ended.

On the phone with Bobby Denney in Maryland some weeks after the show, his first remark was, “You guys put on one hell of a show”. To which I replied, “Thanks, that means a lot. Would you like to come and help out next year?”

Big heart, clear eyes

After telling you all that we go through each year to get ready for and put on Decorative Concrete LIVE!, you might think that I have no heart. The opposite is true, I’m actually looking for people with a big heart, because that’s the industry I have known for the better part of 25 years. And its what will keep this industry thriving for another 25 years.

A month before the show Keith Duffy with Kickass Concrete in Hawaii called to ask if he and his guys could get involved. I told him I would have to discuss his ideas with our team of planners. This team, who are worth noting, include Emil Gera, Chris Becker, Rebecca Fuscardo, Rick Smith, Brian Farnsworth & Jeff Kudrick. The group helped with the layout of the space and deciding what types of concrete activities we would showcase. This decision-making process was made possible with product support from our many sponsors, highlighted below, who we encourage you to patronize this year.

After the team’s approval to include Keith Duffy and his crew, they were thrilled to be a part of the space. They brought that true Aloha spirit with them and were a pleasure to work with. The “Concrete Octopus” they created was bigger than life. However, that larger than life demonstration was essential in calling attention to the humanitarian crisis in Hawaii following the tragic wildfire last year, for whom they dedicated their art to.

As the world turns

Our centerpiece this year was the concrete globe by Emil Gera. It was one of the best photo-ops we have ever seen at a tradeshow. It also reminded audiences that concrete’s structural value includes a world of aesthetic capabilities too.

When Emil found an 8′ diameter inflatable beach ball on Amazon, he knew his vision could come to life. He was able to create the circumference for a GFRC concrete globe using this recently acquired beach toy. The hope to create this globe onsite at the Las Vegas Convention Center eroded quickly when the project proved too labor intensive. Since construction had slowed dramatically in Pennsylvania, Emil’s shop became the globe’s birthplace. From what I understand, it was a family affair. The electric turn-table was made possible with help from Emil’s neighbor and friend, Dan Zacharias. Even the Rebello brothers and Kingdom Products’, Bart Sacco made weekend visits to help with the project.

Next, the meticulous construction of a shipping crate began. The globe had to safely and securely make its cross-country passage on a flatbed 18-wheeler in the dead of winter. There was a window of time it needed to arrive, but after the long trek, the timing ended up nearly perfect. The globe rolled onto the convention center property just as placement of the concrete slab it would sit on was being finished.

Coating the globe with a gray topping that would sparkle as it rotated in the sunshine was the job of the FirmeCrete staff. Emil requested that concrete colorants not distract industry onlookers. Concrete is gray, and that’s an inherent beauty.

|

|

Opportunities abound

The Decorative Concrete LIVE space was chalk full of activities by artisans at work on a wide range of decorative concrete projects. Afterall, that’s what Decorative Concrete LIVE! is all about. For everyone that visited the space during the show, we want to make sure you know just how integral our sponsors are to the events success.

- ISI’s Viper II vapor barrier stands up to the abuse during forming and placement of concrete slabs. This year the Viper II log was added to a textured concrete slab to recognize their valuable support.

- Chapin sprayers delivered all along the way with applications of form release agents, surface retarders, acid etches, finishing aids, concrete stains and sealers.

- Fox Blocks made insulated concrete wall construction a breeze. Small retaining walls and sitting walls were also constructed with the insulated concrete forms to speed our building process.

- Spiderlath and TruFast products laid the foundation for an array of vertical concrete carving and smooth wall finishes. New fiber mesh made carving applications on ready-to-assemble and ready-to-finish outdoor kitchens by Living Foundations an exciting new business opportunity.

- Solid Solution Products demonstrated that their joint sealants exceed industry standards with a few easy steps. They also created durable accents with control joints that integrate with polished concrete flooring.

- As always, FloorMaps stencils made the application of both simple and complex imagery for concrete floors possible.

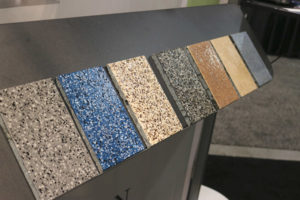

- Scanmaskin equipment showed how effective its equipment is at prepping concrete surfaces for coatings, and turning freshly placed concrete into a fashion statement with polished concrete surfaces.

- HyFlex new VersaMax met the challenge with mixing/pumping and spray applications of scratch and carving mixes onto Fox Block (ICF) walls by Joshua Russell.

- Kingdom Products also provided vertical carving mix for their demonstrations.

- Collomix single and dual-shaft mixers in addition to their TMX1500 Heavy Duty mixers responded successfully to the wide range of materials used. The dual-shaft hand mixer was always in use.

- Spartan Design’s new Speed Cast Pro GFRC mix created precast table tops while producing near flawless finishes with fiberglass molds by Concrete Decor. Its polishable self-leveling bag mix addressed uneven surfaces and created an elegant concrete floor across the aisle in the Spartan Design booth space.

- Redi-Mix Colors stocked the Concrete Decor RoadShow trailer, giving our crew the ulitmate color wheel when adding that extra pizazz to their projects.

- Artisans used Polytek’s 74-45 liquid rubber for making molds to cast rough sawn boards. They then used these to recreate wood planks using GFRC and concrete countertop mixes by both SureCrete and Spartan Design. The results were flawless renderings of the original.

- Roadware demonstrated how its MatchCrete repair products address random cracks and spall on textured concrete surfaces. The repairs utilized onsite color hardeners to match existing surfaces.

- Christopher Land and his crew at Epoxy Guys used SurfKoat metallics and epoxies to create remarkable concrete flooring solutions despite the wet weather and cooler outdoor temperatures.

- Concrete Decor’s Fiberglass Molds were a resounding success once again. With cast concrete elements complimenting a range of concrete flooring solutions, these molds prove perfect for both indoor and outdoor spaces. Stenciled inlays created permanent designs and corporate logos on the statuary type concrete vases.

- Prosoco dyes, densifiers and guards were on hand to ensure that projects were completed professionally and with precise attention to detail.

- Iron Age Designs brought textured concrete finishes up a few notches with a range of classic, modern and industrial design options.

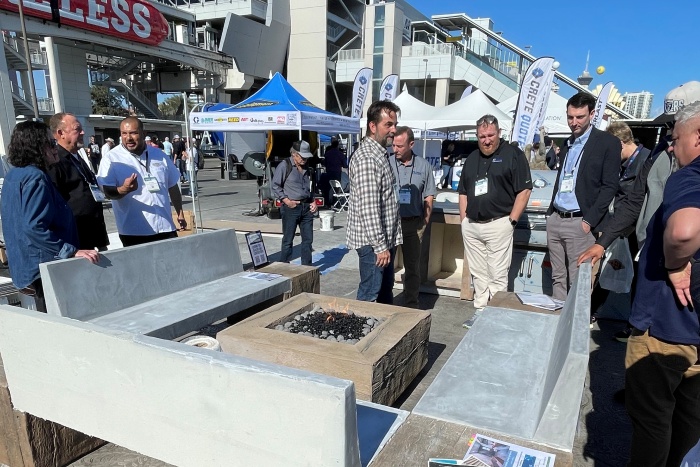

- SureCrete Design Products utilized a range of its decorative concrete products to demonstrate just how versatile these materials are in transforming indoor or outdoor spaces. Its outdoor entertainment space was a hit.

- Elite Plastiform Concrete Forming Systems made the job of creating large and small radiuses both accurate and quick. Lining the flexible forms with lengths of a stone texture step forms from Proline was an added benefit.

- American Specialty Glass made tasteful color accents with polished concrete floors and also with FirmeCrete’s architectural coatings. Both red and orange colored glass gave the appearance of flames with vertical carving applications. In addition, mirror terrazzo glass added reflective qualities when the sunlight touched concrete surfaces.

- Alpha Professional Products supplied diamond abrasives for a range of precast concrete finishing applications. Their products on display inlcuded surface grinding wheels that remove coatings along walls in record time. Alpha also introduced their new Nichigo G-Tape (green tape) product that stops color bleed with a masking tape.

- Proline Concrete Tools made a lasting impression for visitors and the crew alike. New designs and custom logos were on display throughout the Decorative Concrete LIVE! space.

- PDQuipment representative, Danny Carillo showcased both productive mixing and pumping solutions by Putzmeister and Graco. Equipment that have played a valuable part of Decorative Concrete LIVE in previous years.

- Kraft Tool Co. restocked the Concrete Decor RoadShow trailer this year. This assured that our team of concrete finishers had everything they needed for concrete placements, vertical carving applications and overlays.

- ICON Protection, makers of RamBoard and AquaShield floor protection products, kept Decorative Concrete LIVE! neat and tidy despite ongoing weather changes. The proof was there that Icon Protection designs its products to perform in all types of weather.

- Lastly, we want to recognize CemRock’s new MgO board. This is a replacement for both engineered plywood and OSB products. Aside from the materials non-flammability and waterproof characteristics, its use as a sub-floor creates new opportunity. Specification writers can now look to CemRock when choosing micro toppings, self-levelers and waterproofing solutions for both new construction and renovations.

We also want to thank Euclid Chemical, a manufacturer of professional grade building materials. We are grateful for their ongoing support of Decorative Concrete LIVE! In addition, thanks also go out to Quikspray, the maker of mixing and pumping equipment for concrete professionals. Its with the support of them and sponsors like them that make Decorative Concrete LIVE! a success.

Finding support beyond the World of Concrete

In closing, it is organizations like the American Society of Concrete Contractors (ASCC), the American Concrete Institute (ACI), the International Concrete Repair Institute (ICRI) and the newly founded Women’s Association of Concrete Professionals (WACP) among others that all work tirelessly to develop, maintain, and improve industry standards including important specification that both protect our industry and its customers. Our world simply does not turn without their leadership and support.

Let make 2024 a great year! And, let’s do it through ongoing demonstrations of quality workmanship on the job site every day.