According to the news, retail brick-and-mortar facilities are declining at a rapid rate. While I agree 100 percent that internet sales are impacting sales at traditional stores, this market segment is still relevant. And when it comes to polished concrete at retail establishments, business is still booming.

In the realm of retail, we encounter three types of construction: new, open-store remodels and refreshes. There are a few issues you should watch out for in each segment.

New construction

New construction is the most obvious and the easiest segment for contractors to get into. There is a lot of bidding opportunities in the new construction market. I regularly talk with contractors and manufacturers and one of the major issues that comes up regarding new construction is pricing.

Pretty much unanimously, manufacturers are baffled by polished concrete contractors’ “race to the bottom” regarding new construction work. As someone who has reviewed bids on the owner’s side for the last few years, I’m amazed at how low some contractors will go. The only reasoning that makes sense is that contractors put bids out based on two factors.

First, contractors’ bids are the result of the work they have at the time of the bid. This is a big mistake because most new construction projects won’t be ready to polish for six to nine months. By the time the work is ready to commence, contractors are busy again. Because they are contracted already at an extremely low price, they end up missing out on higher-margin work to fulfill their contractual obligations.

Second, contractors submit bids based strictly on what they think a bigger competitor will propose.

Neither idea is good for business. Bids should be submitted with the same formula each time. Perform your takeoff to get the footage of the job, review the specifications to determine the process or requirements of the project, and then figure your specific costs to perform the work.

After you have determined your job-specific costs, add on your overhead costs. Take the aggregate of all your costs and add the profit that you feel would be fair compensation for the job. This number should be your bid price.

This formula will ensure a profit (assuming your crews are competent to perform the work) and will allow you to remain in business much longer. If you lose the project because someone else is willing to take less profit, you must determine if you’re willing to go that low on the next one.

Unfortunately, I see a lot of bids come in that are below the cost to do the work. Each time a low bid is submitted, it gets entered into the general contractors’ databases that they use to figure their budgets for future projects. So, each time you provide an unusually low bid, you are doing damage to the overall price for the work in the industry.

Open store remodel

Open store remodels are by far the most difficult retail projects a contractor can undertake since everything done in a retail environment revolves around the cash register. In all retail segments, open store remodels are a necessity to keep the revenues flowing. It is extremely rare for retailers to close during renovations unless a disaster has occurred.

From a polished concrete standpoint, these open store remodels are very challenging. Typically, the store is broken into phases to be completed before a new phase can be started. When performing polished concrete in this phasing style, one of the biggest issues involves blend lines.

When polishing is done right up to the edge of a phase and then the protection is flipped around, there’s a definitive blend line where the phases join. This can be remedied by explaining to the general contractor at the beginning of the job that you need four feet of swing space at the perimeter of each phase. This will allow for blending and easily remove the scratches at the edge of the grind area.

The other main issue I regularly see with open store remodels is damage to merchandise or fixtures. Proper planning can really come into play here. Scheduling the fixture movement in conjunction with your polishing is a big part of protecting the customers’ property. Using simple products like plastic, painters’ tape and cardboard is always a big help.

One practice I learned a long time ago is to have retailers start saving their boxes about a week before your start date and during construction. Cardboard boxes are easily and readily available and provide a great protection material when they are taped up to cabinetry and fixtures.

Refreshes

Refreshing a retail space is just now becoming widespread in the polished concrete industry. Polished concrete placed over the last 10 years as the industry grew is now ready to be refurbished. This work is typically much easier than the initial polishing.

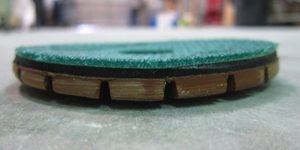

In most cases, refreshing can be completed with resin diamonds only. This work is done overnight and can be completed quickly. Because the work is easier, contractors tend to bid this work extremely low. I’ve seen prices as low as 50 cents per foot for 100, 200, 400, 800 and 1,500 resins even though the average price point is between $1.50 and $2 per square foot.

The biggest mistake made is forgetting to include the cost of hand grinding. There is a lot of hand work on most refreshes because fixtures aren’t being moved. When refurbishing appropriately, you’ll also install densifier and stain protection again as well. These things bring the cost up considerably and sometimes contractors miss these additions.

As our industry continues to mature, more and more retailers are moving toward polished concrete as their preferred finish.