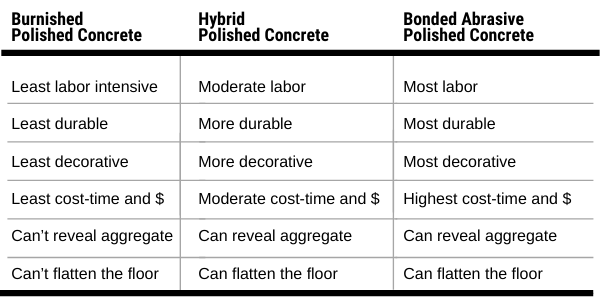

From the last three tips, you’ve learned there are three types of polished concrete with specific differences. For this tip, I’m consolidating the items into an easy-to-read summary. This can be something you can give to your sales team or use as a reference with clients. You can also share it with your estimators so they can devise a way to bid the project.

Here are the major performance and installation differences:

Use this information to your advantage. Educate your customers for both your company’s and their company’s benefit. Most polishing contractors just go on automatic pilot when they hear their customer wants “polished concrete.”

Next time, ask more questions and listen to what they tell you. If a floor needs to be durable and easy to clean — but being decorative isn’t important — the best solution could be either HPC or BPC.

Think bigger. If these floors cost less, then maybe your company can do a second location or another area in their plant. Not overselling can show your customers you care about a long-term business relationship with them versus making the money and running.

Here is the tip

All three types of polished concrete have many similarities. They can:

- Provide any level of shine, from flat to high gloss

- Provide durability, with lower maintenance than other flooring

- Yield a dust-free, permanent floor installation

- Provide a safe floor with a COF of .42 or greater using ANSI standard A326.3

- Provide a breathable floor

- Improve light reflectivity

- Contribute to LEED qualifications

- Provide a low-maintenance, easy-to-clean, sanitary (no-host) floor

What matters most when installing polished concrete is making sure you fulfilled your customers’ expectations, did high-quality work and made a profit. With these guiding principles, your polished concrete division will continue to grow and create more opportunities for success!