Changes occur, and though my change wasn’t as drastic as Victor Kiam’s when he bought the Remington Shaver company back in the 1960s just because he liked the shaver so much, mine was a major change.

In the last column I wrote in 2006, I focused on concrete being truly renewable, and in the article I talked about AmeriPolish and their new penetrating agent. Well, I guess that I wrote a pretty convincing article, at least for myself, because I ended up leaving a position that I enjoyed at RetroPlate to join AmeriPolish as their Vice President, Marketing & Product Development. Changes happen in life — some are controllable, some aren’t. I hope that all of you make the most of them, just as I plan to, because 2007 is looking to be a breakout year for the polished concrete industry, with or without color.

Walking the walk, not just talking the talk, is more important than ever for our young industry. As the polished concrete industry enters its second decade, we’re still the infants of the floor coating and floor covering industry, an industry that is worth more than 25 billion dollars annually. We have an immense opportunity for profitable growth, but this will only happen if we become more professional in our approach, our investment in education, our pricing, and in our treatment and respect for each other. While we are battling over who was first, or who’s the best, the coatings and coverings people are addressing our assault on “their market.” Did you know that Formica now makes a Solid Surfacing countertop called “Real Concrete,” a surface that provides the high-end look of polished concrete? It is an honor to be copied, but only if you take your competition as seriously as they take you.

Walking the walk, not just talking the talk, is more important than ever for our young industry. As the polished concrete industry enters its second decade, we’re still the infants of the floor coating and floor covering industry, an industry that is worth more than 25 billion dollars annually. We have an immense opportunity for profitable growth, but this will only happen if we become more professional in our approach, our investment in education, our pricing, and in our treatment and respect for each other. While we are battling over who was first, or who’s the best, the coatings and coverings people are addressing our assault on “their market.” Did you know that Formica now makes a Solid Surfacing countertop called “Real Concrete,” a surface that provides the high-end look of polished concrete? It is an honor to be copied, but only if you take your competition as seriously as they take you.

|

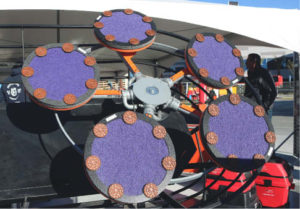

I did not have the opportunity to walk the World of Concrete this year as I have in the past, but from what little I did see, I was excited to see the growth in our industry. I was impressed, not only in the number of manufacturers exhibiting, but in the new or updated products being offered, along with the excitement of both newcomers and industry veterans. Ten years ago everything in our industry was borrowed, whereas now we create for our own. Ten years ago the industry existed to fix failing concrete in industrial facilities. Now with the options of dyes, acid stains, dry shake hardeners and integral color, you have the ability to deliver an exquisite, yet cost-effective, color alternative in place of carpet, linoleum, vinyl, composition tile, terrazzo and stone. If you look at the “food chain,” each additional or successful step fosters growth down the chain. For every gallon of dye, someone buys 2 gallons of densifier; for every square foot you densify, you buy two to eight different grits of diamonds; and as your workload or job size increases, you buy more equipment.

Let’s look at the anatomy of a slab, using AmeriPolish’s slab in our outside booth at the World of Concrete. The WOC slabs are only days old instead of weeks old. Even so, the slab was more real-world than we would have liked, but it’s exactly what could happen on a real job site, just on a smaller scale. Even at only 450 square feet, it still required all steps, all products.

Day One:

We arrived Friday, January 19, in order to set up our equipment for a Saturday morning start. The weather was not looking promising, and the slab was outdoors and uncovered.

Day Two:

We checked our equipment; the vacuum hadn’t been delivered. Change No. 1: We went dry, using a broom and shop vac instead of an industrial vacuum to keep the area clean. At the first test, we realized that we had a soft slab, confirming a soft floor due to freeze-thaw the previous week. Change No. 2: We changed to hybrids and eliminated the metals, as we were concerned with chewing the floor up. After our initial anxiety and a little finger-crossing, we established our ability to proceed. Following our grinding up to 400-grit resins, we cleaned the floor thoroughly and laid out and sawed the graphics lines.

Day Three:

Prior to spraying each color, the area was masked off, ensuring color coverage only on the planned area. With the dyes, it was important to have a clean, dry surface. In addition to the normal masking, we also had to create “portable” walls of cardboard and so forth to stop wind gusts of 40 miles per hour from scattering the sprayed dye.

For each color of dye, one very light application of dye was applied, then a few minutes later, a second was applied. (Always apply the dye with a conical tip, with a consistent spray pattern.) We then moved on to each successive color, taping and applying prior to scrubbing and rinsing the slab to remove the normal dye residues. Change No. 3: History at the WOC dictates that since the slabs are so hard and we are only worried about a few days wear, densifiers are not required. But with the freeze-thaw we experienced, a densifier became a necessity that wasn’t planned on, neither by ourselves nor by many other manufacturers that were exhibiting. L&M graciously provided us with FGS PermaShine in order for us to complete our slab.

Day Four:

We completed our polishing steps of 800-grit, 1,500-grit and 3,000-grit diamonds, and applied our Stain Shield for protection against oil and water-based spills. A polished and densified floor is still concrete and therefore porous to some degree. Additionally, whereas densifiers deliver increased strength and abrasion resistance almost immediately, the tightening up of the floor continues for four to eight months. Late Monday, the floor was completed and ready for the attendees who came for education and entertainment.

Days Five to Seven:

Time to listen, talk and learn.

Day Eight:

We had a good ballgame, appreciative fans, and more than 1,000 hits, but the game was over and it was time to take down the bleachers for another season.

It shouldn’t matter if you’re a Red Sox or Yankees fan. What does matter is that we help educate each other on how to be better players and a more successful team, and learn how to raise the awareness in our industry.

Part of AmeriPolish’s commitment to the industry is training and education, and with that in mind, I will be taking a road trip across North America in 2007, conducting seminars on adding color to polished concrete. I will not only teach the applications of dye, but will also discuss how integral color, dry-shake hardeners and acid stains fit into the mix. The goal is to not only raise the knowledge and expertise of both veterans and newcomers to our industry, but equally importantly, to raise our own knowledge through interaction with all of you in the field. Please contact me at [email protected] to learn more about The North American Dye Guys Tour 2007.