Polished concrete has changed more than any other concrete trade in the last 10 years. It has grown from a fledgling industrial flooring type into a juggernaut in the architectural and retail world. It has been embraced by retailers, schools and hospitals and has an increased presence in the industrial world.

The problem is that as time has gone along, polished concrete has picked up market share and damaged contracting companies at the same time. If the profit margins of this industry do not rebound soon I am afraid that polished concrete will become an extremely rare and specialized process.

While there are a lot of reasons for the loss of margin in this business, I will go into some that are easily controlled and share what I feel is causing them.

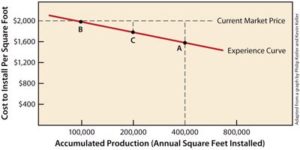

I looked at 15 jobs that were bid and sold in the South in 2008. These were decorative projects, not large industrial. The jobs were spread across multiple market segments including retail, educational, hospitality and small industrial. New construction or remodel, all the prices came in between $4.75 and $6 per square foot.

Then I looked at similar jobs done this year. The results were staggering. For basically the same size jobs in the same market segments the prices were between $2.25 and $3.75 per square foot on the high end. This is a decrease of 63 percent on the low end and better than 35 percent on the high-end jobs.

Now here is the question. Has the cost of doing these jobs gone down this much in 24 months? Has the labor cost gone down? No. Has the cost of our materials gone down? Not that much. So did we have 50 percent or better margins in this business two years ago? No. All my job cost reports showed an average of 20 percent net profit.

So you ask yourself “How are we doing this work for that cheap and making any money”? The answer is that we are not making money.

In today’s market there are very few jobs that make any profit. Most break even at best and if one thing goes wrong then they are losers. One really bad job (assuming that you make it right) can eat all your company’s profits for half the year.

The problem that allows us as contractors to fool ourselves is twofold. We don’t have great cost accounting processes in place yet because we are a newer industry. Also, in our industry most of our projects are spread out over multiple months, or even over a couple of years on the larger projects. This allows us to get distracted by the day-to-day sales, marketing and operational concerns of our business, and we do not see the jobs for what they are. We bill in pieces, and as the saying goes, we rob Peter to pay Paul.

This is compounded by new polishing companies coming in and getting low-cost contracts. Due to their general lack of knowledge as start-ups and their getting pricing from suppliers (whose main goal is to sell their product) that do not always know what goes into a job. That, along with the burning, all-American desire to win work at any cost, creates a perfect storm where the prices keep going down and down until they are below the labor and material cost of doing the job.

How can we change this in our industry? Guys like myself and other industry leaders from the contracting side need to educate our suppliers, contractors and architects about the true cost of doing work and stand by it. On average, on a one- or two-color school job of 20,000 to 30,000 square feet where we charge $4.00 per square foot, the breakdown is 60 to 75 cents per square foot in pure material cost (diamonds, densifier, color, stain protect), including ancillary costs such as paper and tape or blades for scoring saws and so on.

Then you get to the labor. I am only talking about the guys that will actually work on the project, not sales or operations management. This is the most expensive section of our work, running about on average $1.80 per foot on that same $4-per-square-foot floor. This includes labor at $10 to $14 per hour plus the taxes on that labor. So to bring us up to speed we are at $2.55 on labor and materials before we go any further.

Next we consider items like insurance, fuel, phones, truck payments and all the other things that make our business run. This should come in at around another 75 cents or so per square foot, pushing us up to $3.30 per square foot. We haven’t paid the owners of the company anything yet. No maintenance has been accounted for yet. We haven’t figured in the fact that 10 percent of that $4 will be held for up to a year in retainage. We haven’t taken into consideration any travel costs back and forth or shipping for those materials that we need, or any advertising to try to get more work, and we are already at less than 20 percent remaining.

Just so that you don’t think that I am making these numbers up, I looked at more than 20 jobs from three different companies to get these average numbers. You can drop your costs 20 percent to 30 percent by doing jobs 50,000 square feet or larger in one deployment, but there aren’t a lot of those jobs out there anymore.

We need to communicate these facts to our suppliers, so that when they are talking to new companies they are able to give them fair information. I talked to an architect last week on a project. He says that he went to a supplier’s training class to learn more about polished concrete and that in the class they cited polished concrete prices starting at 75 cents per square foot.

When the bids come in low it is a double hit for every company in our business. You don’t make any money, and the low price given sets the new standard for pricing.