Messiah Lutheran Church, Madison, Wis.

Contractor: Specialized Construction Inc., Waterloo, Wis.

To complete a renovation at their local church, members of the Messiah Lutheran Church in Madison, Wis., hired Angus Young Associates to head the project. As it happens, this firm had worked with Shawn Wardall of Specialized Construction Inc. on a previous church, so members of the building committee took a field trip to see firsthand what Wardall’s polished concrete was all about. “They pretty much instantly decided that’s what they wanted to do,” Wardall says.

The main focus of the project was the recently installed slab in the sanctuary. The team at Specialized Construction started with a 50-grit resin polish – but they had to do a little repair work before they could go further. A strategy for protecting the slab had been set during prepour meetings, but the general contractor had instead laid down plywood, and numerous drywall screws crushed under the plywood had wreaked havoc. Hundreds of tiny imperfections on the surface had to be patched using a polymer-modified grout, colored with Precision Pac-Color for Concrete from Alabama Pigments Co. to match the floor’s final surface color.

Once the imperfections were patched, the floor was polished to a 400-grit resin finish, washed, and prepped for dye. Wardall used Consolideck’s water-based GemTone Stain in Light Roast for the floor under the seating area, creating a two-tone effect with the slab, which was integrally colored a Stetson Buff tint at the ready-mix plant. After coloring, the floor was densified using Consolideck LS and brought up to an 800-grit resin polish. Finally, three coats of Consolideck LS Guard were applied, with burnishing done between each coat. “Polishing the cream of (ready-mix supplier) Lycon Inc.’s concrete finished to our spec can have the rich look of marble or leather,” Wardall says. “It is one of my favorite finishes.” The patched areas of the floor were not noticeable, he adds.

In addition to the sanctuary, Specialized Construction provided a polished floor for the downstairs social hall. There, they polished to a 200 grit and colored with Consolideck ColorHard in Serpentine. Because ColorHard is designed to be mixed with Consolideck LS or LS/CS, Wardall was able to densify and color the floor at the same time, resulting in less cost for the church.

“We were able to do it for less than half the price as the sanctuary,” Wardall says, noting that the square footage is the same for each space. “The ColorHard is a nice alternative for the cost conscious. We really try to keep the pricing as reasonable as possible with churches.”

Wardall recently visited the church to work out some kinks in the maintenance program, and people were quick to let him know how much everybody loves the floors. “To this day they’re really happy with the work we did,” he says. “It is extremely gratifying to have people so happy with the work we have completed in a space that has such great meaning.”

www.specializedinc.net

Cathedral of St. Mary of the Annunciation, Cape Girardeau, Mo.

Contractor: J.R. Welch Waterproofing and Concrete Contractors, Cape Girardeau, Mo.

When Cathedral of St. Mary of the Annunciation in Cape Girardeau, Mo. decided to have a fountain installed in the church courtyard, they wanted it surrounded by something other than gray. Luckily, one member of the congregation had been pouring decorative concrete for over two decades.

John Welch, owner of J.R. Welch Waterproofing and Concrete Contractors, was able to provide the church with concrete that was far from the usual that they were trying to avoid.

To start, Welch poured concrete curbing and stenciled it with a bushrock header design. He colored it using L.M. Scofield Co.’s Lithochrome Color Hardener, starting with Steadman Buff as a base. He randomly dispersed additional colors of Lithochrome Color Hardener – Pecan Tan, Terra Cotta and Walnut – swirling them in with a hand trowel. He also picked out random “stones” to color with Lithochrome Chemstain Classic in Terra Cotta, Padre Brown and Antique Amber.

Next, Welch and his crew poured the area inside the curb. He textured it using a faux brick stencil in a Keystone pattern from DCI, colored it with a Terra Cotta base, and swirled in colors of Steadman Buff and Pecan Tan using the same method as on the curb. He then applied a Pecan Tan release agent, and ran a slate texture roller to “give it a real rock look and feel,” he says. When the concrete was dry, he power-washed off most of the release, although some remained in the depressed parts of the pattern as an accent.

Around the very center where the fountain was to be placed, he used a Cobble Circle Ring stamp, also from DCI. Steadman Buff served as the base color of the ring, with the Pecan Tan, Terra Cotta and Walnut swirled in, while the smooth center inside the ring remained only the buff color. Like the curb, Welch colored random stones in the cobble circle with acid stain.

Around the fountain, the church wanted the phrase “Hail Mary Full of Grace.” Welch used a stencil to do the lettering and stained it in a walnut color using Chemstain.

Finally, after the concrete had cured for 30 days, Welch applied Dayton Superior Construction Chemicals’ Day-Chem Tuf Seal (J-35), a clear gloss sealer. “It brought out the colors and protects the finish,” he says.

www.jrwelchconcrete.com

Our Savior’s Lutheran Church, Port Orange, Fla.

Contractor: Clines Concrete, South Daytona, Fla.

After raising funds to expand and remodel their church, members of the congregation at Our Saviors Lutheran Church in Port Orange, Fla., stopped by Decorative Concrete Supply and Rental in South Daytona, Fla., to look into ideas for incorporating concrete into their sanctuary, restrooms and reception area.

They originally wanted Clines Concrete (which owns the store) to install stained concrete, but after seeing the store’s sample floor, they preferred the look of stamped concrete. With that settled, Clines Concrete would be responsible for applying a quarter-inch overlay and stamping the surface with the Vegas Seamless Stone stamp from SuperStone Inc.

Shortly before construction began, a woman from the congregation decided she would like to see the Shield of the Trinity, a traditional Christian symbol, added to the floor of the sanctuary. Although it was not a part of the original design plan, the church’s pastor and other members of the congregation agreed it would be a nice touch. The woman even paid for that part of the project herself.

The pastor found a depiction of the Shield he preferred and sent it to Gary Cline Jr., who was in charge of construction for Clines Concrete. Because the shield has too many tight angles to cut with a diamond blade or router, Cline faxed the image to Proline Concrete Tools to be made into a stamp 7 feet in diameter.

The pastor found a depiction of the Shield he preferred and sent it to Gary Cline Jr., who was in charge of construction for Clines Concrete. Because the shield has too many tight angles to cut with a diamond blade or router, Cline faxed the image to Proline Concrete Tools to be made into a stamp 7 feet in diameter.

When the stamp arrived one month later, it was time to get to work. The first step was to position the shield stamp on the floor and draw a pencil line around its perimeter. After setting the stamp aside, Cline sawed a 1/4-inch cut along the pencil lines. Next, the crew applied adhesive weatherstripping to the inner edge of the cut to act as a form.

With that in place, Cline began to focus on the rest of the floor. The crew applied a 1/4-inch overlay using SuperStone Inc.’s Super Surface Stampable Overlay in Adobe Buff and Ivory Sand, added texture, and colored the floor using SureCrete Design Products’ Eco-Stain in Spanish Red, Kayak and Domino. Once the main floor was set, Cline removed the weatherstripping and primed the now-recessed surface where the shield would go. Superstore’s Super Surface was again used as the overlay material, this time in white. The shield stamp was applied, and the results colored with Eco-Stain in Domino, Espresso, Aztec Gold, Oak, Flamingo and Green Olive. The shield was sealed with an initial coat of SureCrete’s Dura-Kote Polyurethane Sealer. A second coat of Dura-Kote was applied as part of the sealer coat for the entire floor. Finally, the floor was treated with three coats of Sure Finish.

“The pastor was in tears when we were putting the Shield of Trinity in the floor,” Cline says. “It meant a lot to him, because it was his teaching tool.”

www.clinesconcrete.com

The Cathedral Church of St. John, Albuquerque, N.M.

Contractor: Faux Real LLC, Albuquerque, N.M.

The building committee at The Cathedral Church of St. John in Albuquerque, N.M. knew they wanted an outdoor labyrinth as part of a peaceful meditation area, so their architect, SMPC Architects, called on Gaye Goodman of Faux Real LLC to create it with decorative concrete.

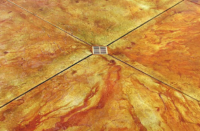

The 361-square-foot, five-circuit labyrinth features a path that winds around in a serpentine pattern, circling the center five times, leading to an area in the center for meditation. John Ridder, a labyrinth expert from Indianapolis, Ind., created the design and flew out to Albuquerque to draw the design onto a pre-existing cement slab with charcoal.

Before the design could be drawn on, the concrete needed to be stained with the background color. Using a mixture of L.M. Scofield Co.’s Lithochrome Chemstain Classic in Padre Brown and Antique Amber, Goodman stained the surface and laid a piece of plastic over the area to give it a marbleized look.

“You must stain the slab in fairly small sections of about 4 feet by 6 feet and get the plastic laid down as soon as possible while it is still soaking wet, or you’ll get no marbling marks at all,” Goodman says, adding that the plastic needs to be left for the full cure time of the stain (usually a minimum of four hours).

The New Mexico winds put up a fight, and the plastic didn’t stay down. “We had to restain,” Goodman says. “We laid the plastic down again, this time with lots of rocks to keep it in place.”

Unfortunately their troubles weren’t quite over. After a rainstorm during the night, a tree located above the labyrinth dropped blossoms onto the freshly colored slab, staining the surface. The discoloration wouldn’t come off, but thankfully the church committee liked the mottled look and considered it “the Lord’s input.”

After cleaning off the slab, it was time for Ridder to draw his design. Once that was complete, Goodman went through and painted liquid latex rubber outside of his lines.

“It acts as a good resist,” she says. “Nothing bleeds under it.”

Once the resist was done, Goodman stained within the lines with Dark Walnut Chemstain to color the walking path in the labyrinth. After the dark stain had cured and the residue was scrubbed off, the crew peeled up the latex rubber resist. A bit of a halo was left around the Dark Walnut edges, and her team touched up some of the lighter areas.

The final step was to apply five coats of Dayton Superior Construction Chemicals’ Day-Chem Tuf Seal (J-35) as the sealer. Although Goodman says it is typically used for parking garages and gas stations, she likes to use it because it stands up to the strong UV rays present in Albuquerque. “For outdoors, when we want a shiny surface that’s what we use now.”

The labyrinth was installed two years ago, and she says it’s still holding up nicely.

www.gayegoodman.com

Holy Nativity Episcopal Church, Westchester, Calif.

Contractor: Steve O’Loughlin, Los Angeles, Calif.

As a public artist in Los Angeles, Steve O’Loughlin is known for his vivid drawings, including those at his neighborhood church, the Holy Nativity Episcopal Church. So when the church was looking to install a Celtic cross on their sidewalk, they contacted him to see if he could do the work.

“I went about finding a way to make it happen, and that’s how I found out about the acid stain process,” O’Loughlin says.

Unfamiliar with decorative concrete and acid staining, O’Loughlin headed to Phoenix, Ariz., to attend a seminar from Tamryn Doolan on her Flattoo system. Flattoos are vinyl adhesive templates that help artisans create intricate designs with acid stains and other colorants. O’Loughlin began practicing at home with his new knowledge, but between scheduling conflicts and wanting to be comfortable with acid staining, it wasn’t until a year later that he was ready to dive in.

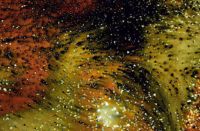

Thanks to root damage from a nearby tree, O’Loughlin was starting with a fresh piece of concrete on which to create the 8-foot by 12-foot cross. He set up a canopy over the area to avoid the hot sun and pine needles falling from the tree above and got to work, laying out 12 Flattoo strips.

As he pulled up a section of Flattoo over concrete that was to be colored black, he etched the surface with Tek Gel for Flattooing. Next he applied the color, using black spray paint before applying a black acid stain. He then washed, neutralized and applied a clear coat before pulling up the next section.

He applied the same methods to the colored areas, although he did not put down a layer of paint first. For the colored sections, he used either L.M. Scofield Co.’s Lithochrome Chemstain Classic in Antique Amber or a hickory color created by combining Titan Concrete Products’ Concentrated Crete Stains in Old Hickory and Midnight Black.

He added some additional touches before applying the sealer. “I did some shading and buffering of the edges to give it depth and to make it pop more,” he says.

Although the cross was his first concrete project, O’Loughlin says it won’t be his last.

“The reason I was attracted to acid-stained concrete was that it holds up outside. Now I have a new medium that is durable,” he says. “From an artistic point of view, it’s an underdeveloped opportunity. Having people walking over the top of it is an experience itself.”

www.stevenoloughlin.com