Whether you create them on site or buy them precast, faux rocks can be a valuable part of your portfolio.

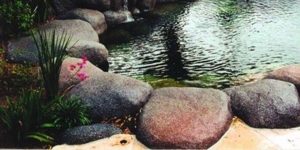

When it comes to putting boulders in a backyard pool or rock garden, concrete “faux rocks” are often better than the real thing.

Faux rock offers the same unique, attractive look and sturdy support for water accents as real rock. It can mimic the look of indigenous stone or be colored and textured to match just about any rock on the planet.

But faux rocks are lighter and easier to work with. Even though rock can cost less than a faux concrete facsimile, the time and labor of planting it in a backyard or pool setting can make up the difference in cost.

Mike Reinwald, general manager of Rock & Water Creations Inc., a manufacturer of precast rock features, says faux beats real rock in two categories — weight and placement.

Rock & Water’s faux rock pieces are formed in molds taken from actual boulders, so the texture is the same. But the glass-fiber reinforced concrete (GFRC) castings, with walls that are only about one inch thick, weigh nine pounds per square foot of coverage. That makes them easy to place and support. “You’ve got the ability to put them wherever you want,” Reinwald says.

A real boulder, he notes, takes up more space under the ground than on top of it. It’s the tip of the iceberg, so to speak. A faux rock piece exists completely above ground.

Going with real rock limits contractors to rocks that are indigenous to the area, says Tim Phelps, national sales manager for Boulder Image Inc., which sells the Techstone system for creating faux rock installations. “And real rock, you can’t chip and shape any way you want.”

Going with real rock limits contractors to rocks that are indigenous to the area, says Tim Phelps, national sales manager for Boulder Image Inc., which sells the Techstone system for creating faux rock installations. “And real rock, you can’t chip and shape any way you want.”

A rock that is four cubic feet might weigh as much as 6 tons, he says. “You almost have to bring it in with a crane,” he says, adding: “You don’t have to tear up the yard to install faux rock.”

Then there’s the matter of plumbing, part of any pool remodel or waterfall installation. Plumbing installers must work around real rock, sometimes even tearing out an existing deck to install piping. With faux rock, plumbing can be built into the hollow shell.

In fact, plumbing or not, a real rock installation will likely require that the existing deck be removed to construct a foundation that will support it.

In fact, plumbing or not, a real rock installation will likely require that the existing deck be removed to construct a foundation that will support it.

What’s more, Phelps says, real rock must be embedded in mortar. Any temperature swing may cause cracks in the mortar bed, and the mortar erodes into the pool. “The things we do don’t erode at all,” he says.

Waterproofing natural rock waterfalls poses a special challenge, says Bruce Riley, managing director of Rico Rock LLC, a manufacturer of modular and structural waterfalls. Water will seep out hairline cracks where the grout joints meet the natural rock. Even with a waterproofed base, calcium deposits could seep out the back of the base. “It’s almost impossible to waterproof natural rock waterfalls from the top side,” he says. “You can’t just cement large rocks together and expect them to hold water.”

Faux rock also allows the contractor to shape a stream of water to an extent that is hard to do with natural rock, Riley says. When water cascades over a lip of natural rock, it typically curls over the edge. If the waterfall designer wants a sheet of falling water, he or she has to install something that clashes with the natural look of the boulder, such as a lip of slate.

Faux rock also allows the contractor to shape a stream of water to an extent that is hard to do with natural rock, Riley says. When water cascades over a lip of natural rock, it typically curls over the edge. If the waterfall designer wants a sheet of falling water, he or she has to install something that clashes with the natural look of the boulder, such as a lip of slate.

How it’s done

There are as many ways of creating a faux-rock installation as there are faux rock manufacturers.

At Boulder Image, the process starts with Styrofoam blocks or cinder blocks. They are put together with rebar and spray foam. “You glue the styrofoam into the rough shape you want,” Phelps explains. “Basically, that’s your subsurface. You can incorporate plumbing into that.”

A Techstone filler mix that contains Styrofoam aggregate is packed over the top of the structure. After about an hour, a second application of filler goes over the first. The first application leaves a nice hard shell, but a structure that looks like a blob, Phelps says. The second time defines the look of the boulder. “At that point, you’re drawing the rock shapes out.”

After that dries, the contractor cuts deeper grooves between the individual ‘rocks’ with a margin trowel.

Then, after cleaning, comes a topcoat that leaves a hard polymer-modified cement shell. The cement is 100 percent acrylic because many other polymers will emulsify in water. After that, a waterproofer is applied where wetting will occur.

Texture is applied next, with yet another layer of acrylic cement. For moss rock, pat the material on with rubber gloves. For granite with stipple, shoot the surface with a hopper gun. For sandstone, use the hopper gun, then wet sand.

Finally, there’s the tint, achieved by spraying chemical stains over the surface. “Most real rock gets color from some kind of oxidation process,” Phelps notes. “That’s what you’ve got to replicate with faux rock.”

The stain is similar to acid stain, only without the acid, he says. “There’s no need to open it up. The pores are big enough already.”

The number and sequence of colors applied depends on the desired effect. Six or seven layers of color will create the illusion of depth, Phelps says. Boulder Image provides color sequences and combination designs to help contractors along.

The number and sequence of colors applied depends on the desired effect. Six or seven layers of color will create the illusion of depth, Phelps says. Boulder Image provides color sequences and combination designs to help contractors along.

Finally, the rock must be sealed. Boulder Image suggests a 22 percent solid acrylic sealer. Calcium deposits and the like will be easy to clean off, but the rock won’t glimmer with a glossy sheen.

A contractor installing a precast Rock & Water Creations piece starts by putting in a cinderblock wall with rebar, then placing the panels. “We use a standard concrete mix with mesh in between panels,” Reinwald says. “The embossers get the mesh to match.”

As for coloring, Rock & Water begins with a spray acrylic coat of antique white or oyster shell. Then, they use acid stains — a brownish color for sandstone, for example — or the contractor may mix a dry color into the color coat. “We teach contractors in large jobs how to get a color for their area,” Reinwald says.

Rico Rock strives to make faux rock installation as simple as possible, says Riley, adding that installing his company’s modular component kit requires only “good masonry skills.” This sets them apart from faux rock firms that expect installers to be skilled in coloring, concrete construction and blending castings, he says.

Rico Rock strives to make faux rock installation as simple as possible, says Riley, adding that installing his company’s modular component kit requires only “good masonry skills.” This sets them apart from faux rock firms that expect installers to be skilled in coloring, concrete construction and blending castings, he says.

Rico Rock’s pieces are filled fiber-reinforced concrete (FRC), as opposed to the hollow pieces sold by other rock firms that require backing. “The texture is done. They’ve been colored,” Riley says. “They’re all waterproofed and preplumbed. Some waterfalls you can actually install in one hour.”

Protecting against water

Protecting against water

Stockton, Calif., concrete contractor Herb Keener says the biggest challenge he faces with faux rock is leakage.

Water seeps into the concrete and activates lime and chemicals in the mix anywhere it’s not sealed, causing big, ugly white strips to appear, he says. “They leach out white, ugly stuff.”

Keener, president of Keener Construction Inc. and distributor for Boulder Image, says that his choice of sealer depends on whether the job is indoors or out. Inside, he applies a plastic membrane anywhere water will be flowing, and outdoors, a Boulder Image sealer.

As scary as leaks sounds in theory, Phelps of Boulder Image says it can be easily avoided. “It’s just too easy to do it right,” he says. “If you follow the recommended process, you’re just not going to have any leaks.”

When it comes to waterproofers, the choice is between a cementitious coating and a rubber-plastic hybrid gel that leaves a plastic surface and bridges gaps, he says. “Personally, I like to use Eurostone deck coating over the top because it’s white. I like cemetitious coats because they dry more quickly. Other guys like the gel because it’s bright red. It’s almost impossible to miss a spot.”

When it comes to waterproofers, the choice is between a cementitious coating and a rubber-plastic hybrid gel that leaves a plastic surface and bridges gaps, he says. “Personally, I like to use Eurostone deck coating over the top because it’s white. I like cemetitious coats because they dry more quickly. Other guys like the gel because it’s bright red. It’s almost impossible to miss a spot.”

Mike Reinwald of Rock & Water Creations says that sealing isn’t always necessary when installing a Rock & Water product. “It’s meant to be underwater in pools and ponds,” he says. “It’s meant to have water flowing over the top of it.”

A waterfall installation on a concrete pool deck is on a surface that is already sealed, he notes. “Customers may not want to spend the extra money to seal it.”

If a Rock & Water rock is sealed, Reinwald recommends spraying with an acrylic color coat before applying acid stain to color it. “Acid stains won’t adhere to sealed concrete, but they will adhere to acrylic color coat.”

If a Rock & Water rock is sealed, Reinwald recommends spraying with an acrylic color coat before applying acid stain to color it. “Acid stains won’t adhere to sealed concrete, but they will adhere to acrylic color coat.”

Beyond the pool

Waterproofing is only an issue if a faux rock installation includes water. These days, faux rock is used for much more, according to Jim Jenkins, president of Dura Lite Rock Inc. and JPJ Technologies Inc., which runs the School of Faux Rock Construction.

Three decades ago, faux rock mainly went into pools, spas and the like, he says. Today, it’s being put to a growing number of creative uses, from covering a pipe in a backyard to casting outdoor patio furniture, and from jazzing up a security installation at a military base to giving an outdoor kitchen the look of limestone. “The demand for this type of training is just growing by leaps and bounds,” he says. “The demand for synthetic rock of all kinds is high. If you just do waterfalls and rock, you’re missing the mark on possible sales.”

Three decades ago, faux rock mainly went into pools, spas and the like, he says. Today, it’s being put to a growing number of creative uses, from covering a pipe in a backyard to casting outdoor patio furniture, and from jazzing up a security installation at a military base to giving an outdoor kitchen the look of limestone. “The demand for this type of training is just growing by leaps and bounds,” he says. “The demand for synthetic rock of all kinds is high. If you just do waterfalls and rock, you’re missing the mark on possible sales.”

Faux rock can even replace the labor-intensive work of stone artisans, he says. “We’ve taken the artistry out of it. A good mason can only do so many square feet a day.”

Faux rock can even replace the labor-intensive work of stone artisans, he says. “We’ve taken the artistry out of it. A good mason can only do so many square feet a day.”

Sheets of rocklike veneer may be hung on the side of a house, and a shaped hunk of concrete will make a sign or fire pit that is just as attractive as one made with a mason’s box of rocks, but for only a fraction of the cost.