What could have been a concrete demolition job turned out to be a benchmark building project for Klassen Concrete, of Winnipeg, Manitoba.

In August of 2010, the Assiniboine Park Conservancy in Winnipeg contacted Randall Klassen, owner of the design/build firm, to get a quote for the demolition and removal of the Assiniboine Park Zoo’s Tropical House. The house, which opened in 1968, had fallen into disrepair. The conservancy wanted to replace it with a rocky tropical oasis for animals, birds and plants native to South and Central America’s rain forests.

When Klassen learned the job’s scope, he wanted in on the action and bid on the project. He had worked on projects involving vertical rock before, with Nathan Giffin, owner of VerticalArtisans.com, an online school, and Shellie Rigsby, owner of Acanthus Inc. Concrete Stain Designs, based in Plano, Texas. “The people at the zoo didn’t know a local was capable of doing the job,” he says.

He won them with over with pictures, workable numbers and a convincing methodology. In September 2010, he was awarded the contract to build Toucan Ridge, the first new exhibit of the zoo’s redevelopment plans.

Improvements to the facility’s infrastructure totaled $900,000, while the redesign and rebuild of the exhibit cost $2.2 million.

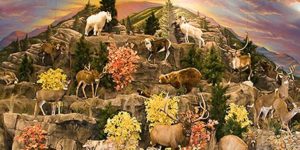

“Toucan Ridge brings together a beautiful mix of tropical animals, birds and plants for a one-of-a-kind experience,” says Margaret Redmond, president and CEO of the conservancy. “It’s impossible to describe how impressive and unbelievably beautiful the new space is.”

Inspired by Costa Rica

To understand the environment and make the exhibit realistic, Klassen and his wife spent three days in Costa Rica. While there, he took hundreds of pictures in the country’s Northern Lowlands, including the magnificent La Fortuna Waterfall near the Arenal Volcano.

With the pictures as an aid, he mapped out a design, which included 11 waterfalls and planting beds. “The zoo changed a few things, but for the most part we stuck true to our original design,” Klassen says.

Although his company does landscaping, he adds, the zoo’s horticulture department was responsible for the project’s planting.

He says he constructed the pathways in the oval-shaped Toucan Ridge so that you can’t see to their ends. Instead they curve this way and that, making you move farther in to see around corners.

“It was very important that we created interesting observation points and photo op areas where visitors could see through trees and capture different elements of the waterfalls,” Klassen says. One area that he’s particularly proud of features a 2-by-8-foot glass wall where people can view one of the cascading waterfalls up close.

Rocking the exhibit

For five months, Klassen and his crew of 12 constructed massive rockscapes for Toucan Ridge.

Probably one of the most innovative methods they used involved creating subsupports for the waterfalls with Fox Blocks insulated concrete forms supplied by his cousin, Glen Klassen. “Using the ICFs saved us two weeks of work,” Randy Klassen says.

Basically, they set the ICFs in place, built plywood floors, and then cut a hole at the bottom of each form. Next, they poured the concrete into the forms. It flowed freely into the open floor space before filling the void in the 2-to-6-foot-high walls. This created a watertight system, he says. “And we were able to control the pour easily.”

Once the support was in place, they built wood substructures with rebar grids for the rock formations above and then shotcreted everything. “We could shoot 15 meters of concrete a day without a problem,” he says, “and put the carve coat on the next day.” He says that while most contractors put the carve coat on first and finish with the shotcrete, “we felt like we had more control with the carve coat on top. And it was faster.” The project involved more than 1,500 bags of Vertifaux, a vertical carve coat from Specco Industries.

A little help from his friends

To help the crew get up to speed in rock sculpting, Klassen hired Giffin of VerticalArtisans.com to hold an on-the-job training session. Giffin divided the group into thirds, assigned them each jobs and rotated their positions for the first three days, working with each group individually. “On the fourth day I worked with those who had the best knack,” Giffin says. “On the fifth day, I oversaw what they learned and made corrections.”

Giffin’s teaching philosophy involves eventually letting crew members shape, sculpt and texture while he films the work, which he later posts on his website. “This way they can reflect on what they’ve done and review what they’ve learned. It helps them work through their problems.”

After the sculpting was complete, Rigsby went to Canada to help Klassen in the color department.

Their unconventional coloring techniques involved using a SATA HVLP sprayer to mist varying shades of translucent blacks and greens onto the gray carve coat. “It was the best spraying system I’ve ever used in my life,” Klassen says.

With the base coat done, the coloring team worked closely with the zoo’s horticulturists, who advised them on where color would naturally be on the rock and how it would occur over time. They devised a repeatable system where they soaked pieces of high-grade sphagnum moss in blacks, browns, yellows, blues and greens, forced them into the rocks’ nooks and crannies, and chased them with water. They achieved the colors they wanted “in days instead of centuries,” Rigsby says.

“We also worked from top to bottom to allow the vibrant but still translucent colors to travel the way water would travel in a rain forest. It accumulated in some places and naturally fell to lower areas.”

In the end, some of the soaked moss was left in place and some replaced with fresh moss. Rigsby says they also applied buttermilk and yogurt to places where they wanted to encourage moss growth.

Back in the saddle

Back in the saddle

“I’m very grateful in many ways for this job,” says Klassen, who notes this is his biggest job ever. Even beyond that, it gave him a boost he desperately needed to get back on track in his profession.

A year and a few months before he landed the job, he broke his neck and fractured his skull and a vertebra in a motocross race accident. “It was a very bad accident and I’m very lucky to be alive. I was still wearing a neck brace when I got the zoo job.

“I had gone through a bad depression and this job and working with my guys were two of the things that helped me recover quicker,” he says. “You’re really only as good as your guys. And right now I look really good because I have really good guys working for me.”

Project at a Glance

Client: Assiniboine Park Conservancy, Winnipeg, Canada

Contractor: Klassen Concrete, Winnipeg, Manitoba, Canada | www.klassenconcrete.com

Scope of Project: Demolish the Assiniboine Park Zoo’s original Tropical House and design/build Toucan Ridge, an exhibit that showcases a habitat recreating the tropics of Central and South America. It includes 11 waterfalls and houses a wide assortment of animals, birds and plants.

Duration of project: Five months

Most challenging aspect: To keep to the original timeline and complete the project by a set-in-stone opening date although the client kept adding to the scope of the work.

Products Used: Fox Blocks Insulated Concrete Forms, Specco Speccrete Vertifaux, Smith Paints Color Wall stains, Colormaker Aquacolor pigments, Solomon Colors Slate (similar to Brickform Rough Stone) and Brickform Cracked Earth texture mats, shotcrete and ready-mix concrete from City Mix Inc., SATA HVLP sprayer