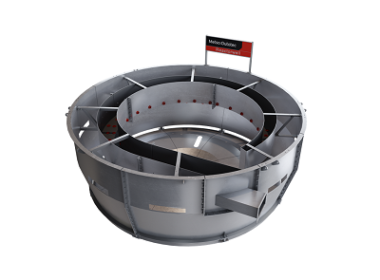

Metso Outotec is launching the Metso Outotec Reactorwell. This is a new generation feedwell for maximizing thickener and clarifier performance. It does this while minimizing flocculant consumption and bringing significant operational cost efficiencies. The first-class feed system features high solids retention and mixing efficiency. It eliminates feed short-circuiting and offers […]

Tag: Job Site Efficiency

The Mobile Charging Pod by Makinex

We all know what a job box is. Don’t you wish it could do more?! Introducing the latest innovation from Makinex: The Mobile Charging Pod (MCP). This innovative, secure storage pod provides a safe way to store power tools, chargers, battery banks, and more. In addition to providing secure storage […]

Stronghold Quick-Switch System by Pure Safety Group

Pure Safety Group is launching the Stronghold® Quick-Switch® Total Tether System for the prevention of dropped objects during work at height. The system is based on Quick-Switch, the only technology that allows workers to switch tools from one connection point to another in one motion to provide a level of safety from dropped objects unmatched in the industry.

Electric Machines Can Ease Workload

In the category of wheelbarrows, this one packs a heck of a lot of power. Electric wheelbarrows and mini skid-steers can ease manual labor.

Technological Improvements Up Advantages of Cordless Tools

Chances are good that by now you’ve been on a job site with other trades using cordless tools. You may even have a few of your own — and with good reason.

PVC Pipe, Leftover Diamonds, Paint and Chalk Put to Work on Decorative Concrete Jobs

Make line cuts with a Dremel rotary tool Using a Dremel hand-held rotary tool for freehand line cuts in decorative concrete greatly decreases the time it takes and increases the accuracy of the cut. It is a small rotary tool with high rpm, and it’s relatively easy on the budget. […]

How to Protect Your Concrete Work Surface on the Job Site

Each job your company completes is a billboard. Each project says, “Yes, my company is good and worthy of your next decorative project,” or it says, “I’m a work in progress that right now, unfortunately, is not worth the chance.” Few billboards imply anything in between. At the end of […]

Dealing with Wastewater and Sludge from Concrete Countertops

Concrete-making uses water. Cleaning concrete-covered mixers, tools and buckets uses even more water. Add to that the sludge that’s rinsed out and you’re often left with a big mess. Everyone who makes concrete faces this dilemma: what to do with all that dirty water and gritty sludge.

How to Store Partially-used Concrete Sealers

One-part concrete sealer products are easily stored for reuse in the future. Of course, you want to avoid foreign contaminants, so don’t pour back into the container what you may have portioned off unless you strain the used material first.